Quite often heard about the "Compression Ratio"? it is a relative term used for any internal combustion engine including your motorcycle's engine. There is lot written about the topic and you can find out quite a bit on various sites on internet, but frankly speaking even I found it little difficult to understand the technical phenomenon as it is explained in different websites. Understanding the need of explaining the terminology in a much simpler way, here I tried to simplify the whole process to make you understand the Compression Ratio better.

Quite often heard about the "Compression Ratio"? it is a relative term used for any internal combustion engine including your motorcycle's engine. There is lot written about the topic and you can find out quite a bit on various sites on internet, but frankly speaking even I found it little difficult to understand the technical phenomenon as it is explained in different websites. Understanding the need of explaining the terminology in a much simpler way, here I tried to simplify the whole process to make you understand the Compression Ratio better.When we talk about the mileage or the performance of your motorcycle, couple of technical things are always taken into consideration; the compression ratio is one of those. You might have heard that the modern motorcycles or the superbikes are all having engines with higher compression ratio, so before we move any further I want you to remember that the "Higher the Compression Ratio the better it would be".

Compression Ratio:

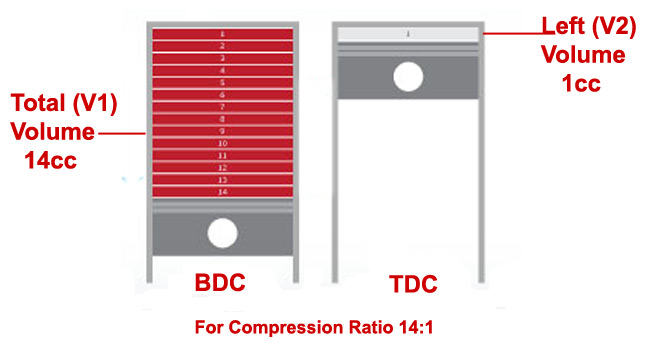

Theoretically the compression ratio is the ratio or the fraction of the volumes before and after the piston moves from BDC (Bottom Dead Center) to TDC (Top Dead Center). Isn't it confusing???? let's try to understand it in a much simpler way:

Now, suppose when the piston is at the bottom end of the cylinder (position called as BDC) the space or volume left in the cylinder (including the combustion chamber) is 1400cc (V1) and when the piston moves from this position to the other top extreme position (also called as TDC), the remaining space or volume left is 100cc (V2).

In this case the compression ratio will be 1400:100 and further simplifying it will become 14:1. Now you must have noticed that practically the difference between the volumes before and after the piston moves from its both extreme ends determines the compression ratio. Considering this calculation you can get maximum compression ratio by increasing the V1 or by decreasing the V2 and to increase the Volume 1(V1) you can either increase the Bore size or the Stroke size or you can increase both Bore & Stroke size of the engine.

Why Higher Compression Ratio is better?

Why Higher Compression Ratio is better?As mentioned this earlier at the beginning of the article, its time to understand the importance of higher compression ratio. In an internal combustion engine the temperature plays very vital role, as we all know that when we talk about petrol engines the compression process involves the compression of fuel (petrol) and air mixture. When the piston moves from BDC to TDC it actually compresses the mixture of air and fuel and as a thumb rule of science the more you compress the gasses the more the molecules of the gasses gets activated and the maximum temperature attained.

If the mixture of air and fuel is not compressed optimally or in other words the compression ratio of the engine is lower, then the molecules of the gasses would not reach to the state of optimum activity and neither the temperature reaches to its desirable reading and when the combustion takes place with the spark generated from the sparkplug, it would not only result into poor performance but would also return poor mileage.

Drawbacks Of Higher Compression Ratio:

So, now you know it's all about volume game, to get the gasses compressed efficiently, you need volume. But there are drawbacks of the higher compression ratio engines as well, the air & fuel mixture when compressed in a higher compression ratio engine, there is a chance of self-detonation, as fuel with lower octane rating is tend to combust at comparatively lower temperature and hence resulting "Knocking" which ultimately spoil the whole purpose of the higher compression ratio engine. As knocking prevents the gasses to reach the maximum compression and the mixture of air and fuel (with lower octane rating) explodes well before the piston reaches to the TDC compressing the gasses to its maximum.

To avoid the knocking every manufacturer recommends use of specific octane value fuel, generally premium fuel with higher octane rating is recommended. There are other ways also to counter the early detonation at the higher compression engines, putting up "Knock Sensors" are one of those commonly used in racing bikes which are known to have engines with high compression ratio as much as 14-17:1.

Earlier when the premium fuel was not commonly available manufacturers were compelled to produce engines with comparatively lower compression ratio, as low as 7-8:1 but when technology evolved and higher octane fuel is radially available along with gadgets like Knock-sensors, the bikes with 11:1 compression ratio are now become common sight.

By: Farhan Kashif