The concept of Variable Displacement is not new; however, very few automakers have tried their hands at the technology. As the name suggests it is all about engines which can alter/vary their displacement. Generally the big sized multi cylinder engines are found equipped with this piece of technology, the reason behind the advent of these types of engines is to counter the poor fuel economy associated with them.

The concept of Variable Displacement is not new; however, very few automakers have tried their hands at the technology. As the name suggests it is all about engines which can alter/vary their displacement. Generally the big sized multi cylinder engines are found equipped with this piece of technology, the reason behind the advent of these types of engines is to counter the poor fuel economy associated with them.Imagine riding a big 4 cylinder engine on a highway, how long one would cruise at 200-250 kmph?? Cruising on highways at high speeds has its limitation, after all it‘s all about cruising and not racing on highways, isn’t it? It is said that a powerful big machine utilizes only about 30% of its total capacity on highways, still all of its cylinders kept firing and engulfing expensive fuel. There should be a way to get us out of this situation and there comes “Variable Displacement Engines” for the rescue.

Variable Displacement Engines:

Normally when a multi cylinder engine cruises at a constant speed, the throttle valve is partially opened; this creates an inefficiency best known as “Pumping Loss”. This can be understood as when the throttle valve is partially opened the engine has to work harder to suck air inside the cylinder through the small opening. This creates a vicious cycle as now engine has to struggle with the partial vacuum created in the cylinder along with the extra drag the piston is experiencing due to low cylinder pressure.

The entire episode leads to inefficiency as the engine was struggling with the above mentioned complications rather than delivering outright performance. Poor fuel efficiency is caused by both Pumping Loss and the unnecessary fairing of all the cylinders where there is no need of out and out performance from the engine.

Cylinder Deactivation:

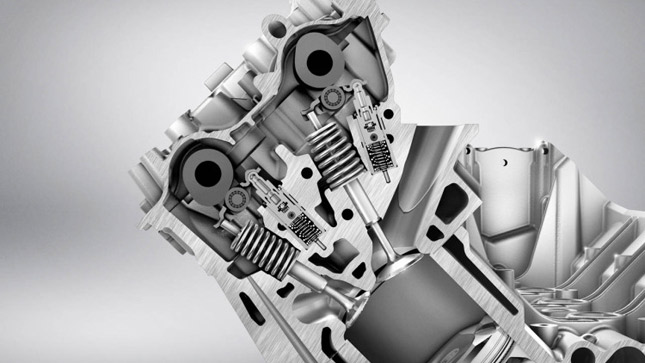

In Variable Displacement Engines the overall displacement of the engine can be altered by many ways, Cylinder Deactivation is one of the means by which the variable displacement can be done. The cylinder deactivation can be achieved by closing the intake and exhaust valve of a cylinder for a time being. There are more than one ways through which the temporary closure of intake and exhaust valves can be attain. Normally it is done by the use of hydraulically actuated Solenoid.

When the Valves are closed there is a spring of air left in the cylinder from the previous piston cycle when the valves were open and the combustion had done successfully. This spring of air is now being compressed and decompressed in place of the fresh charge of air and fuel, which otherwise would have been there if the valves were not closed. This result into normal movement of piston without any unwanted drag or low pressure created whatsoever.

To accompany the process of Cylinder Deactivation, now a day ECU plays a big part, it controls the firing order of the cylinders, cuts of the ignition for the deactivated cylinder and most importantly cuts off the fuel supply through the Fuel Injection System. Another factor that plays vital role in administering the entire process is by monitoring the Throttle positioning system. All and all it takes fraction of seconds to complete the process with the help of these sophisticated gadgets.

One can save fuel from 8-25% without compromising on performance while cruising on highways with the help of Variable Displacement engines. The cylinder deactivation is only one of the many ways through which we can achieve the Variable Displacement engine, in the near future we will address the another unique process “Piston Deactivation Engine” through which variable displacement can be achieved by deactivating the Piston movement all together. Till then stay tuned to BikesIndia for more on automobile technology.

By: Farhan Kashif