A GP motorcycle is an optimized machine to get the desired acceleration, top speed, braking and stability. Every effort put on these bikes are just to increase and maintain those parameters, on the expense of comfort and fuel economy. Engineers do many alterations and hours of explorations in their designing, manufacturing and assembling, which is proved right or wrong by endless amount of testing on the race tracks. What follows are the insights of technology that goes through each and every part of a MotoGP bike.

A GP motorcycle is an optimized machine to get the desired acceleration, top speed, braking and stability. Every effort put on these bikes are just to increase and maintain those parameters, on the expense of comfort and fuel economy. Engineers do many alterations and hours of explorations in their designing, manufacturing and assembling, which is proved right or wrong by endless amount of testing on the race tracks. What follows are the insights of technology that goes through each and every part of a MotoGP bike.1. Engine

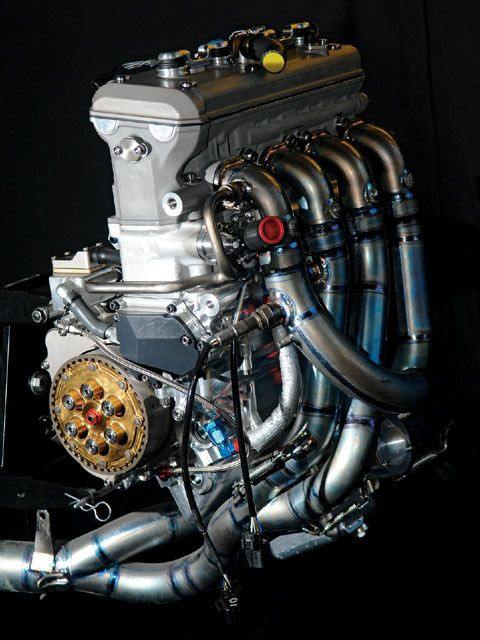

It is obvious that the very first difference exists in the power producing heart of these bikes. As per the current MotoGP regulation one can use a maximum of four cylinders and a capacity of one litre. Manufacturers use two types of configurations at present, V4 and Inline four. A Racing bike incorporates much lightweight engine which produces a mammoth amount of power compared to a production bike. These engines can produce around 20%-30% more power than a normal production engine, thanks to its ultra lightweight components and higher Compression Ratio.

The current MotoGP engines are capable of making around 260 hp. Each and every part of the engine gets special consideration from the designers. Much lighter alloy castings are used instead of normal aluminium alloy casting, in order to reduce weight. Steel parts are replaced by stronger and lighter Titanium parts. Now most machines use Carbon fibre parts in the engine as a solution for weight reduction. The Clutch is also operated as a dry unit and there is no casing above the fly wheel of the engine. As production costs stay very high, there is no room for any blunders and the manufacturing with precision.

2. Air intake and Throttle

2. Air intake and Throttle Air ducting in Racing bikes plays an imperative responsibility in the Bike's performance. As it is the only means by which the bike engine breaths sufficiently and efficiently, the air intakes are slot in a straight and simplest way to provide adequate amount of fresh air. The fresh oxygen also helps to increase volumetric efficiency.

*** Central Air intake duct

The throttle bodies in these bikes are advanced and very sensitive with the use of butterfly valves. By the use of "Ride by Wire" technology, there is no direct mechanical connection between the throttle and the butterfly throttle opening. It is replaced by an electronic sensor at the throttle, which opens the butterflies according to the input given by the rider. Just a small twist of the wrist can open the butterfly wide which amplifies the bikes acceleration tremendously. This helps to avoid more twisting of rider's wrist and reduces the fatigue, considering the long race duration.

*** Butterfly Valves

3. Exhaust System

They look the simplest part of the engine, but are highly engineered and precisely manufactured. This contributes a lot to gain and retain the desired performance by increasing the scavenging (process of removing the exhaust gases) efficiency of the engine. Though the exhausts are "Free Flow", a number of sensors are integrated on it, to read out the temperature of exhaust gases, oxygen and carbon dioxide. With this data, the ECU and other electronics helps to increase the power output.

*** Full Titanium exhaust system

4. Clutch and Transmission

Almost all racing bikes use "Slipper Type Clutch". It is a multiplate clutch that allows the rider to downshift aggressively while cornering, without worrying about locking the rear wheel. Difference exists in the materials used to manufacture these type of clutches, and are 10%-20% lighter than the conventional ones. They also transmit power more efficiently, which is a key aspect of a GP bike.The transmission acts as a deciding factor for the bikes acceleration. The bike can't have great acceleration if the transmission chosen is erroneous.

As acceleration is the deciding factor of victory, each crew tries hard all through the race weekend to have the accurate gear box that provides the highest acceleration. The gear shifts are now done in fractions of a second, by use of "Quick Shifters". These quick shifters have an electronic sensor, that senses a downshift or upshift and cuts the engine firing for that very moment resulting in a very quick gear shift.

*** A Quickshifter

5. Chassis

The chassis is the second main component on which designers concentrate for the much possible weight reduction. The most vastly used frames are made of aluminium consisting a mixture of cast, extruded and forged pieces. KTM has even used "Trellis Frame" for its MotoGP venture, which is a pipe based frame. Nowadays, manufacturers even use Carbon fibre chassis for great weight reduction and stability.

A GP bike frame stays almost 35% lighter than other production frames. The "Swingarm" is also a part of the chassis, which has a slight bit of elasticity while cornering. This slight amount of elasticity provides ample feedback to the riders in the fast corners, helping to understand the bikes characteristics. The swingarms are made up of Aluminium or a mixture of aluminium alloy and carbon fibre.

*** Aluminium chassis of a Honda RC213V

6. Brakes

Plane Carbon discs are now universally used on all GP bikes which offer great heat dissipation and considerably less expansion under heating. They also help in reducing the bikes weight, compared to steel discs. These carbon discs need to be at an optimum temperature for its efficient operation. So, in case of cold weather or rain, conventional steel discs are replaced. ABS seems worthless on racing bikes, as the riders go beyond the limits to get that extra advantage over others.

Brake pads used here are heavy duty and lasts longer due to the use of composite materials in the process of manufacturing. This is done because these materials do not change their characteristics under thermal stress.

*** Carbon discs deployed on a Honda RC213V

7. Suspensions

Almost all GP bikes use "Inverted Telescopic Forks" up front and mono shocks at the rear. Although there are no cavities on the racetrack, suspensions are required to transfer the weight from the front to rear during acceleration and vice versa. Suspension has to absorb various forces at the time of cornering, including the banking of corners. Due to this, the setup is always on the harder side. For instance, Yamaha uses two different damping characteristics for the two front forks. One is used for elongation while the other is used for compression. This helps to customise the suspension setup according to the need of the rider.

8. Wheels and Tyres

8. Wheels and TyresThese high performance machines incorporate forged wheels which are ultra lightweight compared to conventional alloy wheels. The wheels are made up of Magnesium alloys, Carbon fibre and other composite materials. Marchesini Wheels is one supplier, that makes these type of Forged wheels.

The most important aspect of putting all the power onto the tarmac, is done by the tyres. As the GP bikes are ridden on well laid and dry roads most often, Slick tyres are used. Slick tyres don't have any treads, in order to generate the maximum contact patch between the rubber and tarmac. The external conditions, rider feedback are vastly used in designing them. These tyres wear out at a specific distance, and cannot be used more than that. More advancement in the tyre technology lead to asymmetric tyres, which has an upper hand in terms of grip and stability. These asymmetric tyres have a harder compound at the centre and softer compounds at the sides, to reduce degradation in straights and provide high grip around corners.

The most important aspect of putting all the power onto the tarmac, is done by the tyres. As the GP bikes are ridden on well laid and dry roads most often, Slick tyres are used. Slick tyres don't have any treads, in order to generate the maximum contact patch between the rubber and tarmac. The external conditions, rider feedback are vastly used in designing them. These tyres wear out at a specific distance, and cannot be used more than that. More advancement in the tyre technology lead to asymmetric tyres, which has an upper hand in terms of grip and stability. These asymmetric tyres have a harder compound at the centre and softer compounds at the sides, to reduce degradation in straights and provide high grip around corners.

*** Bridgestone BATTLAX Racing Slicks

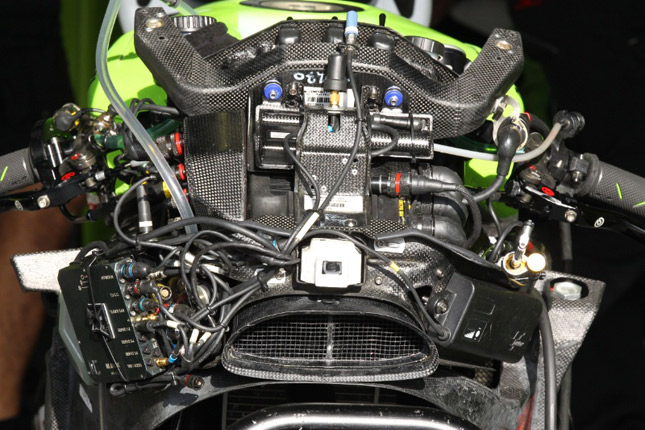

9. Electronics

Electronics play the most vital part in modern day GP racing. Each and every parameter is monitored and fed to the ECU (Engine Control Unit). These modern electronics paved way for the designers to get rid of some bulky mechanical parts. The ECU helps in controlling the amount of power delivered from the engine. Launch Control is a feature used to launch the bike during race starts at around 10,000 rpm from stand still, without the fear of a bad roll over. Traction Control, Slide Control and Wheelie Control are some of the other features used to control the engine power. The crew could get the performance data of the engine and various other components of the bike in real time on their computer screens.

*** Electronic Module

10. Aerodynamics

Fairings are a very obvious requirement for these bikes, considering the amount of speeds they reach. These bikes reach almost the takeoff speed of certain aircraft. In order to have the required down force, aerodynamically tested fairings are used. They have smooth and simple structure without any complicated curves, as they would lead to instability at high speeds. Manufacturers have gone a step up and used Winglets (little aerodynamic wings) to provide much more downforce. Ducati's GP15 machine was incorporated with large winglets, which they claim to provide about 10 kilograms of downforce at ~300 kmph. The fairings are always made of Carbon fibre to be strong and also light in weight.

By: Aravind Rb

By: Aravind Rb