Shaft drives are something that you don’t really see that often in bikes today, but back in the day, it was a huge deal. There was a very good reason for it though. Shaft drives are something that is good to have on your bikes, period. Yes, today there are chain and belt drives available, but still there is something about shaft drives that make them so much special. So in this article we are going have a look at the shaft drive mechanism in bikes.

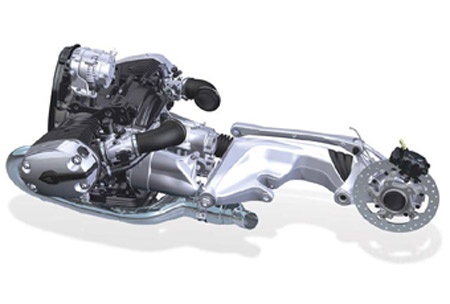

Shaft drives are something that you don’t really see that often in bikes today, but back in the day, it was a huge deal. There was a very good reason for it though. Shaft drives are something that is good to have on your bikes, period. Yes, today there are chain and belt drives available, but still there is something about shaft drives that make them so much special. So in this article we are going have a look at the shaft drive mechanism in bikes.First, one has to understand what a shaft drive is. Like in chains, the chain is the link between the engine cog and the rear wheel to transmit the power to the rear wheel of the bike. The same way the shaft works with Bevel gears instead of regular cog gears because the movement of the shaft is different compared to that of regular chains or belts. The bevel gears are connected to one another in a right angle / 90 degrees. So the engine gear rotates the shaft which then rotates either clockwise or anticlockwise depending upon the setting done on the bike and hence the power is transmitted to the rear wheels.

The best and open use of shaft drives are in today’s trucks. If you happen to get a chance to glance below a moving truck, you can easily check out a rotating road below and that is the shaft drive system in action. Just in bikes, the shaft drive is covered completely leaving no part of it exposed to the atmosphere. There is a very good reason for that which we will come to in some.

The best and open use of shaft drives are in today’s trucks. If you happen to get a chance to glance below a moving truck, you can easily check out a rotating road below and that is the shaft drive system in action. Just in bikes, the shaft drive is covered completely leaving no part of it exposed to the atmosphere. There is a very good reason for that which we will come to in some.So when the engine is working, the output gear of the engine rotates the shaft using a bevel gear. This shaft then rotates and transmits the power to the rear wheel via another bevel gear in place. This way the rear wheel rotates and the power transmission is done, just like how a chain does. But there is an issue here. The efficiency levels of bevel gears are a bit less compared to the usual gears. This is why there is quite some power loss that takes place in the power transmission process which decreases the overall power output of the bike.

Also the issue with shaft drives is that they are heavy, hence the overall weight of the bike increases, thus decreasing the power to weight ratio of the bike. Plus they are quite an expensive unit to have on the bike at the very beginning. Compared to it, bikes with chain drives and belt drives cost quite cheap, but then what the initial expenditure gets you is much more than you think.

Shaft drives have one issue though which is one of the reasons why there was a need to find a newer power delivery system. Since they work on 90 degrees bevel gears, the drive system in case of sudden acceleration made the chassis of the bike rise, increasing the bike’s ground clearance and rider seat height. Similarly when the bike decelerated, the level would come down. Of course companies like BMW did try and sort out this issue, but it was not a foolproof solution after all.

Shaft drives has various other advantages. For starters it is probably the quietest drive systems after belt drives. The reason for this is because it is completely covered and the moving parts are all a snug fit. Adding to it, the constant lubrication provided makes it a much more silent mode. Coming to the reason for it being covered is because since the entire system is working of gears, there is a constant need for lubrication to keep it running smoothly at all times. For this reason the entire system is filled with gear oil which only needs periodic replacement depending upon the use of the system.

Shaft drives has various other advantages. For starters it is probably the quietest drive systems after belt drives. The reason for this is because it is completely covered and the moving parts are all a snug fit. Adding to it, the constant lubrication provided makes it a much more silent mode. Coming to the reason for it being covered is because since the entire system is working of gears, there is a constant need for lubrication to keep it running smoothly at all times. For this reason the entire system is filled with gear oil which only needs periodic replacement depending upon the use of the system.So if we look at it that way, shaft drives are actually better on paper. It has low to almost zero maintenance, add to that it has a longer life than chain and belt drives, i.e. they need proper servicing or rebuilding after over 1,50,000 kilometers or even more. And we all know that most bikes don’t even last that long until they get upgraded to something else. Also shaft drives are suspended on one end of the bike. This meant the bike could pretty much do with just a single leg of the swingarm. The advantage this gave was the access to the rear wheel was simple. All it took was a couple of nuts to pop the rear wheel out and also took out the hassles of wheel alignment and wheel balancing.

But then again when we look at the practical standpoint, shaft drives is old technology and it loses out to other drive systems is only because the newer systems are more agile (i.e. they are more efficient in terms of quick shifts), more efficient and most importantly are cheap with less initial cost to acquire it.

But then again when we look at the practical standpoint, shaft drives is old technology and it loses out to other drive systems is only because the newer systems are more agile (i.e. they are more efficient in terms of quick shifts), more efficient and most importantly are cheap with less initial cost to acquire it.By: Pratik Patole