Expansion Chambers play extremely vital role when it comes to 2-Stroke engines and their performance. Those beautifully crafted tuned pipes that you must have seen on 2-stroke performance machines are not for aesthetics, they are custom built for generating those extra horse powers. The genesis of the Expansion Chambers dated back to the Second World War era. However, surprisingly the invention of the Tuned Pipes took place for better fuel efficiency rather than the insane performance. It is only later discovered that the expansion chamber can not only increase the fuel efficiency of the 2 stroke engines but in fact also augment the power output of the mill.

Expansion Chambers play extremely vital role when it comes to 2-Stroke engines and their performance. Those beautifully crafted tuned pipes that you must have seen on 2-stroke performance machines are not for aesthetics, they are custom built for generating those extra horse powers. The genesis of the Expansion Chambers dated back to the Second World War era. However, surprisingly the invention of the Tuned Pipes took place for better fuel efficiency rather than the insane performance. It is only later discovered that the expansion chamber can not only increase the fuel efficiency of the 2 stroke engines but in fact also augment the power output of the mill. READ ALSO: Why 2-Stroke Engines Are More Fun Than 4-Stroke Engines?

Two Stroke engines are always not frugal in nature and the reason behind is the functioning of the engine. The 2-stroke engines tend to waste fuel in multiple ways; the combustion cycle in 2-stroke engines is responsible for mixing fresh fuel charge into the already burnt fuel. Another trait of a two stroke engine is mixing of exhaust gases into the fresh charge. All and all, there is considerable lose of fuel takes place in 2-stroke engines, it is for this reason the 2-stroke technology being either banned or discouraged worldwide. The 2-stroke technology is considered as not only less frugal but also polluting in nature.

A German Engineer back in 1938 invented the Expansion Chamber for better utilization of fuel in 2-stroke engines. Later the Expansion Chambers were being used for better performance in motor racing when the technology was transferred from Germans to the Japanese.

Working Of Expansion Chamber-

Working Of Expansion Chamber-The Expansion Chamber works on the principal of wave front or the pressure wave generated by the exhaust gas. The basic idea behind the working of an Expansion Chamber is to utilize the pressure of the exhaust gas and the pressure wave generated in the first cycle to suck some more intake charge to the combustion chamber.

Similarly, in the second cycle the same wave front is utilized to close the door/gateway at the combustion chamber restricting the exhaust gas to mix with the fresh intake charge (air and fuel mixture), both resulting efficient fuel combustion and enormous power generation.

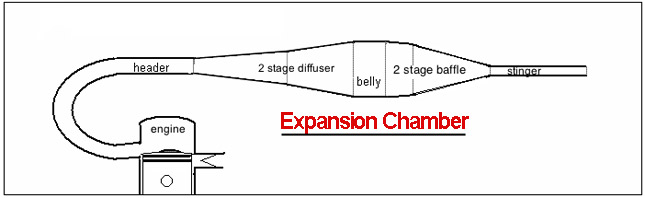

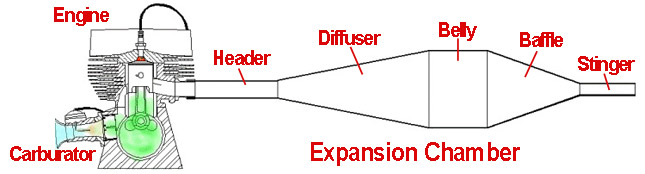

An Expansion Chamber or a Tuned Pipe is typically divided into 5 separate parts-

An Expansion Chamber or a Tuned Pipe is typically divided into 5 separate parts-1. Header: The header is directly attached to the cylinder of the engine and the diameter of it remains constant until it meets to the next section of exhaust chamber i.e. Diffuser.

2. Diffuser: The Diffuser is a conical structure and it is where the expansion of the cross-section begins. At the Diffuser the exhaust gas coming from the Header suddenly expands creating a vacuum or a suction effect. This effect helps sucking extra intake charge in the combustion chamber and burning of which result into extra power output.

3. Belly: The Belly is the next section of the Tuned pipe, meant for giving space to the expanded gas coming from the Diffuser. It also helps in not cancelling the wave travelling forward from the Diffuser and the wave coming back from the next section- Baffle.

4. Baffle: The Baffle Cone is the section which comes right after the Belly and it is just opposite to the Diffuser in shape. The smaller section of the Baffle cone creates a return pressure wave which travels altogether back to the cylinder and it closes the doorway of cylinder preventing the piston to push intake charge out of the exhaust port. This effect virtually save the precious fuel to be wasted and it also added extra thrust to the piston which aids to the better compression resulting increased power out.

5. Stinger: The Stinger is the last section of any Expansion Chamber and like the first part of the tuned pipe it also has constant diameter throughout. Although, it might look like most of the work is done in the mid section of the chamber but the last Stinger is equally important as it greatly affects the performance of the Diffuser and Baffle, therefore the length and diameter of Stinger plays vital role and must be calculated with utmost accuracy.

Problems Associated With Expansion Chamber-2. Diffuser: The Diffuser is a conical structure and it is where the expansion of the cross-section begins. At the Diffuser the exhaust gas coming from the Header suddenly expands creating a vacuum or a suction effect. This effect helps sucking extra intake charge in the combustion chamber and burning of which result into extra power output.

3. Belly: The Belly is the next section of the Tuned pipe, meant for giving space to the expanded gas coming from the Diffuser. It also helps in not cancelling the wave travelling forward from the Diffuser and the wave coming back from the next section- Baffle.

4. Baffle: The Baffle Cone is the section which comes right after the Belly and it is just opposite to the Diffuser in shape. The smaller section of the Baffle cone creates a return pressure wave which travels altogether back to the cylinder and it closes the doorway of cylinder preventing the piston to push intake charge out of the exhaust port. This effect virtually save the precious fuel to be wasted and it also added extra thrust to the piston which aids to the better compression resulting increased power out.

5. Stinger: The Stinger is the last section of any Expansion Chamber and like the first part of the tuned pipe it also has constant diameter throughout. Although, it might look like most of the work is done in the mid section of the chamber but the last Stinger is equally important as it greatly affects the performance of the Diffuser and Baffle, therefore the length and diameter of Stinger plays vital role and must be calculated with utmost accuracy.

1. Expansion Chambers along with all of its plus points are difficult to manufacture.

2. Every Expansion Chamber must be custom built.

3. Heavy calculation is required to make a perfectly tuned expansion chamber.

4. There must be a precision in the tuned pipe building, without accuracy and precise calculation one cannot expect the desired results from the Expansion Chamber, however, miscalculation may cost you engine damage.

By: Farhan Kashif