Internal Combustion (IC) engine is a simple yet complicated thing. Though it contains just a limited number of parts, a slight variation in any of them can drastically change the way in which your motorcycle functions. The Conrod or Connecting Rod is one such essential component. A longer Conrod will essentially turn your engine into a long stroke one. Thus making it function like the engine of a Classic 350. So let’s dive in deep and understand what functions a Conrod performs.

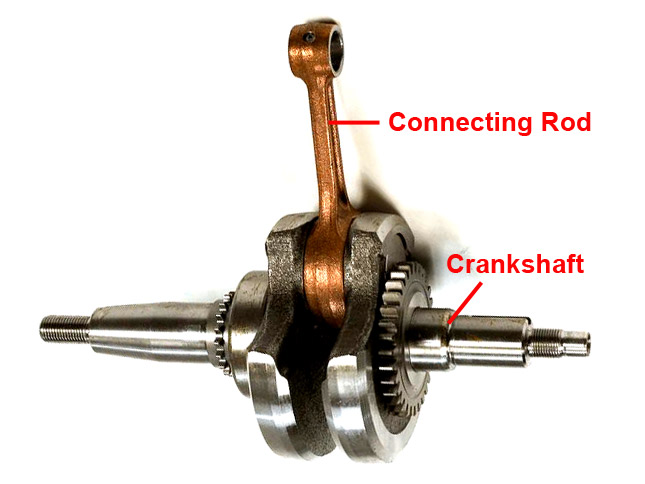

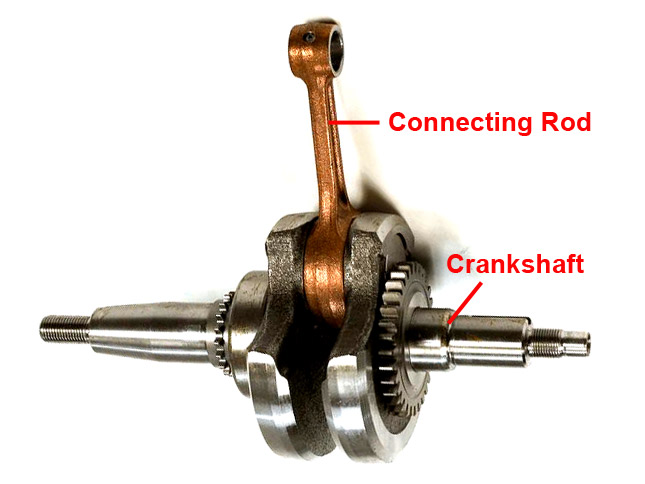

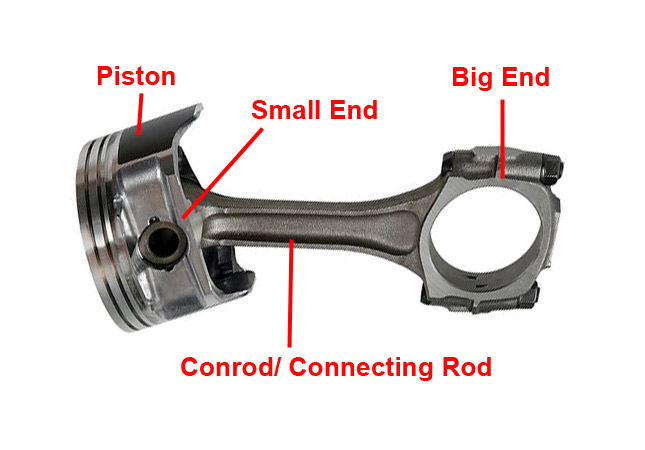

The main function of a Connecting Rod is to connect Piston and Crankshaft. It is an intermediate member of the Cylinder and Crankshaft. The Piston pin receives the push and pulls (reciprocating motion) from the Piston and transfers this motion to Crank pin.

The main function of a Connecting Rod is to connect Piston and Crankshaft. It is an intermediate member of the Cylinder and Crankshaft. The Piston pin receives the push and pulls (reciprocating motion) from the Piston and transfers this motion to Crank pin.

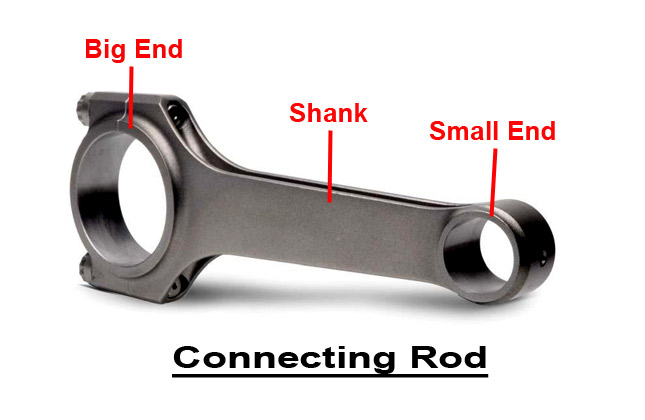

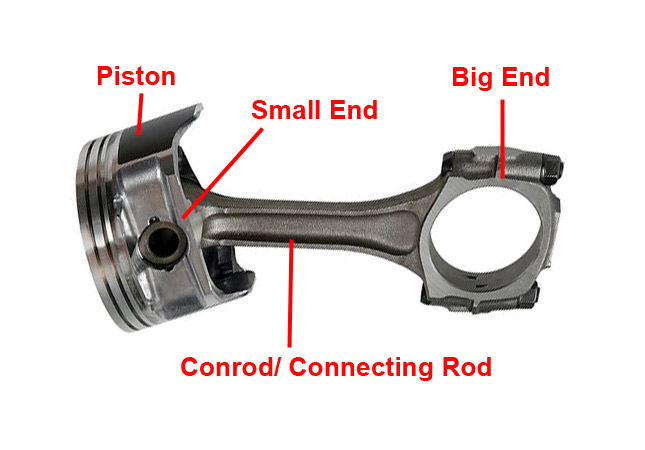

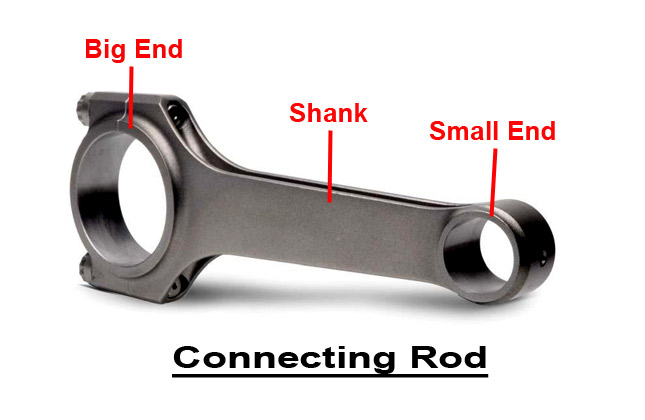

A Connecting Rod mainly contains three parts- Shank, a small end and a big end. The small end of the Conrod is connected to the Piston via Piston pin also known as 'Gudgeon Pin' and the big end is connected to the Crankshaft. The big end can be easily divided into 2 parts, thus making the process of mounting it over Crank shell bearing, easy. The small end is lubricated through pressure lubrication and the big end is lubricated through splash lubrication.

A Connecting Rod mainly contains three parts- Shank, a small end and a big end. The small end of the Conrod is connected to the Piston via Piston pin also known as 'Gudgeon Pin' and the big end is connected to the Crankshaft. The big end can be easily divided into 2 parts, thus making the process of mounting it over Crank shell bearing, easy. The small end is lubricated through pressure lubrication and the big end is lubricated through splash lubrication.

Splash Lubrication System:

In splash lubrication, a sprout is attached at a certain angle in the bearing end. So when the Connecting Rod travels downwards the sprout gets dipped in the lubricating oil. This oil reaches the big end through this sprout. This sprout causes a splash when the Connecting Rod travels upwards that’s why this process is known as splash lubrication.

Pressure Lubrication System:

In pressure lubrication, holes are drilled near the end of Connecting Rod and oil is injected with pressure through these holes. The Cross-section of the Connecting Rod can be rectangular, tubular, circular, or I section. Connecting rods are mainly manufactured using “Drop Forging” method. We use a variety of materials in making Conrods ranging from mild carbon steel and Alloy steel.

The length of the Connecting Rod depends upon the formula:

“L/R”, where “L” is the length of the shank and “R” represents the radius of the crank.

The ratio of “L/R” determines the length of the rod. If the length of any Connecting rod is less, then the resulting “L/R” ratio is also small. This ratio also affects the angularity in the crank. As the “L/R” ratio decreases, angularity in crank increases, which results in more side thrust over the Piston. Thus causing more wear of cylinder lining. In the other scenario if the “L/R” ratio is more, because of increase in the length of the Conrod then it’d result in small angularity in the crank. This will cause less side thrust on the Piston and less wear on the cylinder lining. Increasing the length of the Conrod has some disadvantages also. Longer Connecting rods will increase the height of the engine so most of the time the “L/R” ratio is kept between 4 and 5.

In the other scenario if the “L/R” ratio is more, because of increase in the length of the Conrod then it’d result in small angularity in the crank. This will cause less side thrust on the Piston and less wear on the cylinder lining. Increasing the length of the Conrod has some disadvantages also. Longer Connecting rods will increase the height of the engine so most of the time the “L/R” ratio is kept between 4 and 5.

So, these are the basics which will help you if you’re trying to learn more about your motorcycle or finishing your mechanical engineering assignment ;) Do let us know in the comments what you think about the article and all that stuff which you guys would like us to talk about i the future. Until then, for everything related to motorcycles, stay tuned to BikesMedia.

By: Yetnesh Dubey

The main function of a Connecting Rod is to connect Piston and Crankshaft. It is an intermediate member of the Cylinder and Crankshaft. The Piston pin receives the push and pulls (reciprocating motion) from the Piston and transfers this motion to Crank pin.

The main function of a Connecting Rod is to connect Piston and Crankshaft. It is an intermediate member of the Cylinder and Crankshaft. The Piston pin receives the push and pulls (reciprocating motion) from the Piston and transfers this motion to Crank pin.

A Connecting Rod mainly contains three parts- Shank, a small end and a big end. The small end of the Conrod is connected to the Piston via Piston pin also known as 'Gudgeon Pin' and the big end is connected to the Crankshaft. The big end can be easily divided into 2 parts, thus making the process of mounting it over Crank shell bearing, easy. The small end is lubricated through pressure lubrication and the big end is lubricated through splash lubrication.

A Connecting Rod mainly contains three parts- Shank, a small end and a big end. The small end of the Conrod is connected to the Piston via Piston pin also known as 'Gudgeon Pin' and the big end is connected to the Crankshaft. The big end can be easily divided into 2 parts, thus making the process of mounting it over Crank shell bearing, easy. The small end is lubricated through pressure lubrication and the big end is lubricated through splash lubrication.Splash Lubrication System:

In splash lubrication, a sprout is attached at a certain angle in the bearing end. So when the Connecting Rod travels downwards the sprout gets dipped in the lubricating oil. This oil reaches the big end through this sprout. This sprout causes a splash when the Connecting Rod travels upwards that’s why this process is known as splash lubrication.

Pressure Lubrication System:

In pressure lubrication, holes are drilled near the end of Connecting Rod and oil is injected with pressure through these holes. The Cross-section of the Connecting Rod can be rectangular, tubular, circular, or I section. Connecting rods are mainly manufactured using “Drop Forging” method. We use a variety of materials in making Conrods ranging from mild carbon steel and Alloy steel.

The length of the Connecting Rod depends upon the formula:

“L/R”, where “L” is the length of the shank and “R” represents the radius of the crank.

The ratio of “L/R” determines the length of the rod. If the length of any Connecting rod is less, then the resulting “L/R” ratio is also small. This ratio also affects the angularity in the crank. As the “L/R” ratio decreases, angularity in crank increases, which results in more side thrust over the Piston. Thus causing more wear of cylinder lining.

In the other scenario if the “L/R” ratio is more, because of increase in the length of the Conrod then it’d result in small angularity in the crank. This will cause less side thrust on the Piston and less wear on the cylinder lining. Increasing the length of the Conrod has some disadvantages also. Longer Connecting rods will increase the height of the engine so most of the time the “L/R” ratio is kept between 4 and 5.

In the other scenario if the “L/R” ratio is more, because of increase in the length of the Conrod then it’d result in small angularity in the crank. This will cause less side thrust on the Piston and less wear on the cylinder lining. Increasing the length of the Conrod has some disadvantages also. Longer Connecting rods will increase the height of the engine so most of the time the “L/R” ratio is kept between 4 and 5.So, these are the basics which will help you if you’re trying to learn more about your motorcycle or finishing your mechanical engineering assignment ;) Do let us know in the comments what you think about the article and all that stuff which you guys would like us to talk about i the future. Until then, for everything related to motorcycles, stay tuned to BikesMedia.

By: Yetnesh Dubey