MotoGP has always been a sport of innovations, some things which even Albert Einstein or Isaac Newton wouldn't have imagined and implemented are applied in this outrageous and exciting sport.

Motorcycle manufacturers have always been on the quest to reduce lap times and increase the competitiveness in the sport, whereas the group of engineers working backstage are on the quest of loopholes ready to be exploited by them. Honda has been the front-runner in exploiting them from a long time and its their new invention that decimated the competition and set a benchmark in motorcycle power transmission- The Seamless Shift Gearbox.

Previously, MotoGP machines used quick-shifters to reduce upshift times and manual effort of using the clutch while upshifting. The mechanism eliminated the use of the clutch or closing the throttle but cuts the ignition by using the mechanical pressure sensor mounted on the gearshifter linkage, reducing the upshift time to half. Honda's engineers back in Tokyo weren't satisfied by the already quick upshift times, thus decided to make it even quicker.

READ ALSO: Constant Mesh Vs Claw Shifted Motorcycle Gearbox

A Seamless gearbox as the name suggests, supplies continuous power to the driving wheels of the vehicle without any interruption. This is achieved by using a completely different gearbox layout which eliminates the use of conventional dog clutches or drums in the mechanism, thus making it more compact. Simply put, this gearbox allows one gear to be engaged even before the other gear is disengaged.

READ ALSO: Difference Between Primary Drive and Final Drive

The use of Seamless Shift Gearboxes in Motorcycles date back to the 800cc regulated era, when the Factory Honda machines lacked the hollow "pop" noise which bikes with quickshifters produced during upshifts, owing to the cutoff in ignition. Only one Honda mechanic rebuilt the gearboxes of the four factory Honda machines on the grid.

Honda's system uses cam-like rods and sliding pawls which engage and disengage as you change gears. The gears are on the output shaft and the cam-type rods on one gear disengage in its own when another gear is engaged, thus causing an uninterrupted flow of power to the rear wheels and reduced upshift times. The new gearbox reduced the average upshift time to a whopping 8 milliseconds- in an era when a Yamaha YZR-M1 averaged 27 milliseconds and the Ducati Desmosedici at 42 milliseconds. This means that the Honda gained 19 milliseconds on every upshift on the Yamaha and holds a mammoth 34 Millis on a Desmo.

The new gearbox reduced the average upshift time to a whopping 8 milliseconds- in an era when a Yamaha YZR-M1 averaged 27 milliseconds and the Ducati Desmosedici at 42 milliseconds. This means that the Honda gained 19 milliseconds on every upshift on the Yamaha and holds a mammoth 34 Millis on a Desmo.

Though the system was exceptionally good on full-throttle Upshifts, it struggled in shortshifts and while downshifting. The initial system required the gearbox to be working at high speeds (the RC212V had a 17,000 Rpm redline) to generate the required force to push the pawls off the previous/next gear. The gearbox encountered massive back torque and relied heavily on the back torque limiting slipper clutch for stability under braking. It also relied on the sophisticated electronic riding aids to safeguard the drivetrain on shifts.

READ ALSO: What Is An Overdrive In A Motorcycle Engine?

Ducati and Yamaha followed suit, with the latter developing and using the fully seamless gearbox which works both on upshifts and downshifts for the 2015 season. The change has decimated the competition as the 2015 YZR-M1 won 11 races and took 16 more podiums and the Japanese manufacturer claimed the Triple crown for the 2015 season in dominant fashion.

By: Suraj

Motorcycle manufacturers have always been on the quest to reduce lap times and increase the competitiveness in the sport, whereas the group of engineers working backstage are on the quest of loopholes ready to be exploited by them. Honda has been the front-runner in exploiting them from a long time and its their new invention that decimated the competition and set a benchmark in motorcycle power transmission- The Seamless Shift Gearbox.

*** Marco Simoncelli on the Factory Honda Gresini machine.

Previously, MotoGP machines used quick-shifters to reduce upshift times and manual effort of using the clutch while upshifting. The mechanism eliminated the use of the clutch or closing the throttle but cuts the ignition by using the mechanical pressure sensor mounted on the gearshifter linkage, reducing the upshift time to half. Honda's engineers back in Tokyo weren't satisfied by the already quick upshift times, thus decided to make it even quicker.

READ ALSO: Constant Mesh Vs Claw Shifted Motorcycle Gearbox

A Seamless gearbox as the name suggests, supplies continuous power to the driving wheels of the vehicle without any interruption. This is achieved by using a completely different gearbox layout which eliminates the use of conventional dog clutches or drums in the mechanism, thus making it more compact. Simply put, this gearbox allows one gear to be engaged even before the other gear is disengaged.

READ ALSO: Difference Between Primary Drive and Final Drive

The use of Seamless Shift Gearboxes in Motorcycles date back to the 800cc regulated era, when the Factory Honda machines lacked the hollow "pop" noise which bikes with quickshifters produced during upshifts, owing to the cutoff in ignition. Only one Honda mechanic rebuilt the gearboxes of the four factory Honda machines on the grid.

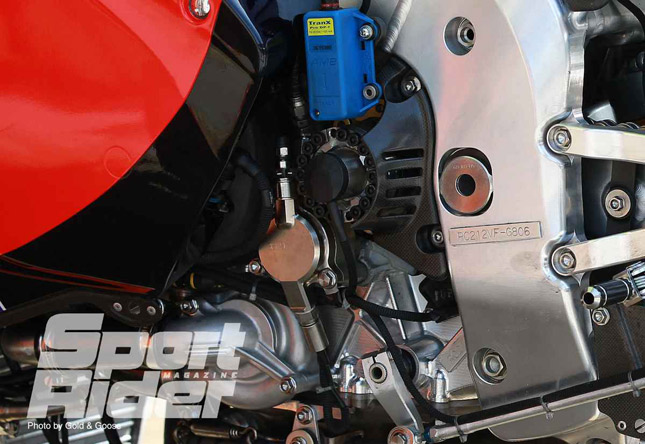

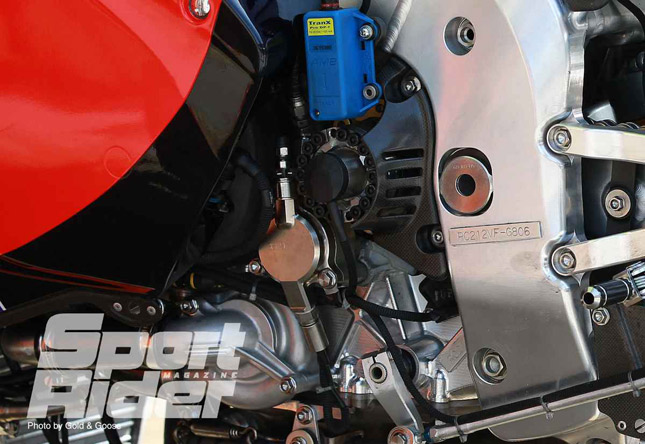

*** The weirdly complicated front sprocket cover on the RCV (source: sportrider magazine)

Honda's system uses cam-like rods and sliding pawls which engage and disengage as you change gears. The gears are on the output shaft and the cam-type rods on one gear disengage in its own when another gear is engaged, thus causing an uninterrupted flow of power to the rear wheels and reduced upshift times.

The new gearbox reduced the average upshift time to a whopping 8 milliseconds- in an era when a Yamaha YZR-M1 averaged 27 milliseconds and the Ducati Desmosedici at 42 milliseconds. This means that the Honda gained 19 milliseconds on every upshift on the Yamaha and holds a mammoth 34 Millis on a Desmo.

The new gearbox reduced the average upshift time to a whopping 8 milliseconds- in an era when a Yamaha YZR-M1 averaged 27 milliseconds and the Ducati Desmosedici at 42 milliseconds. This means that the Honda gained 19 milliseconds on every upshift on the Yamaha and holds a mammoth 34 Millis on a Desmo.Though the system was exceptionally good on full-throttle Upshifts, it struggled in shortshifts and while downshifting. The initial system required the gearbox to be working at high speeds (the RC212V had a 17,000 Rpm redline) to generate the required force to push the pawls off the previous/next gear. The gearbox encountered massive back torque and relied heavily on the back torque limiting slipper clutch for stability under braking. It also relied on the sophisticated electronic riding aids to safeguard the drivetrain on shifts.

READ ALSO: What Is An Overdrive In A Motorcycle Engine?

Ducati and Yamaha followed suit, with the latter developing and using the fully seamless gearbox which works both on upshifts and downshifts for the 2015 season. The change has decimated the competition as the 2015 YZR-M1 won 11 races and took 16 more podiums and the Japanese manufacturer claimed the Triple crown for the 2015 season in dominant fashion.

By: Suraj