I love Quora, there is a lot of cool information on it which you can access and enrich your life for the better. While searching for the answer to “Why Royal Enfield vibrates?” I stumbled upon different sets of answers. Some of them said, that it is due to the “Air-fuel” mixture ratio, some said that it is because of the long stroke cylinder design, which inherently makes more vibrations. So I went on a journey deep within the internet to identify the main culprit of Vibrations so we can create a smooth running Royal Enfield engine.

Please note that all these methods can be universally used, but in this article, I am talking about them in the context of a UCE (Unit Construction Engine) of Royal Enfield.

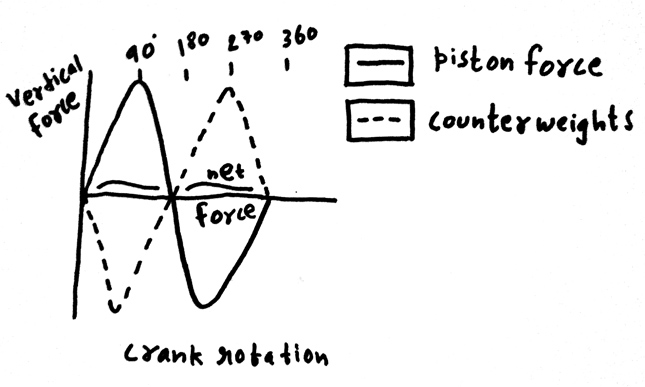

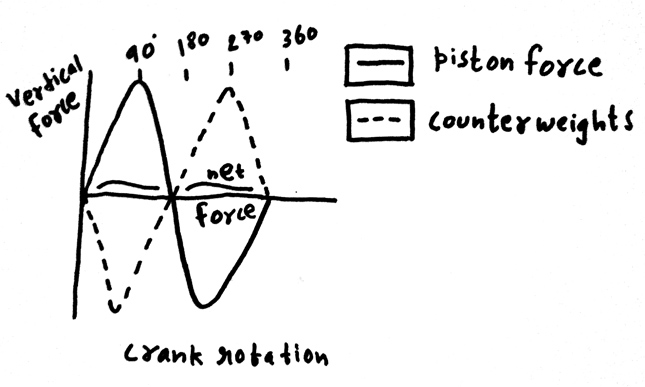

Remove the curse of a Thumper: Look at the Graph, it indicates the primary forces produced by the motion of a single cylinder engine. The first and second half along the horizontal axis indicates two unbalanced forces, now these forces create vibrations when the piston moves. If we see the structure of a piston and Conrod, it is heavy at the top and light at the bottom, this creates an imbalance when the piston moves up and down. To counteract these forces, additional counterweights are added on the opposite end, from the piston, to cancel out the vibrations. It is called Counterbalancing.

Look at the Graph, it indicates the primary forces produced by the motion of a single cylinder engine. The first and second half along the horizontal axis indicates two unbalanced forces, now these forces create vibrations when the piston moves. If we see the structure of a piston and Conrod, it is heavy at the top and light at the bottom, this creates an imbalance when the piston moves up and down. To counteract these forces, additional counterweights are added on the opposite end, from the piston, to cancel out the vibrations. It is called Counterbalancing.

Reduce the age-old flex: Another set of vibrations which emerging from the engine are actually coming from the flexing of the unbalanced crankshaft. The 350 cc engine has 2 bearings on the left side and only one on the right side. The current arrangement results in flexing of the crankshaft on the right side. A solution for this is devised by Paul Carberry, of Carberry Motorcycles, in the form of a Vibration reduction plate. It balances the uneven distribution of mass around the axis thus preventing the crankshaft from flexing. Note that the Vibration due to the Crankshaft occurred only at higher RPM’s so primary vibrations (Emerging from the cylinder) on a standstill, remain unaffected by the plate.

Another set of vibrations which emerging from the engine are actually coming from the flexing of the unbalanced crankshaft. The 350 cc engine has 2 bearings on the left side and only one on the right side. The current arrangement results in flexing of the crankshaft on the right side. A solution for this is devised by Paul Carberry, of Carberry Motorcycles, in the form of a Vibration reduction plate. It balances the uneven distribution of mass around the axis thus preventing the crankshaft from flexing. Note that the Vibration due to the Crankshaft occurred only at higher RPM’s so primary vibrations (Emerging from the cylinder) on a standstill, remain unaffected by the plate.

Add some rubber to it: The engine is a stressed member of the frame meaning it is a part of the structural integrity of the frame. You can check it yourself by following the frame pipe coming down from the steering head. If the engine is a stressed member then that pipe will end where the engine begins. Another point is that most of the parts resting on the frame are made of metal. Meaning if the engine vibrates, then the metal components vibrate because metal tends to resonate. To solve the problem, the frame can be redesigned to enclose the engine and it can be attached to the frame via a number of rubber mounts. Note that these rubber mounts also tend to lose their dampening ability over time so it’s better to make them out of Polyurethane or other similar material.

The engine is a stressed member of the frame meaning it is a part of the structural integrity of the frame. You can check it yourself by following the frame pipe coming down from the steering head. If the engine is a stressed member then that pipe will end where the engine begins. Another point is that most of the parts resting on the frame are made of metal. Meaning if the engine vibrates, then the metal components vibrate because metal tends to resonate. To solve the problem, the frame can be redesigned to enclose the engine and it can be attached to the frame via a number of rubber mounts. Note that these rubber mounts also tend to lose their dampening ability over time so it’s better to make them out of Polyurethane or other similar material.

Another thing which Royal Enfield has done with their LS-410, which they use in Himalayan, is to make it with just 3 pieces.

So upon successfully doing these methods, we can reduce the infamous vibrations of the LS-349 UC Engine of Royal Enfield motorcycles.

By: Yetnesh Dubey

Please note that all these methods can be universally used, but in this article, I am talking about them in the context of a UCE (Unit Construction Engine) of Royal Enfield.

Remove the curse of a Thumper:

Look at the Graph, it indicates the primary forces produced by the motion of a single cylinder engine. The first and second half along the horizontal axis indicates two unbalanced forces, now these forces create vibrations when the piston moves. If we see the structure of a piston and Conrod, it is heavy at the top and light at the bottom, this creates an imbalance when the piston moves up and down. To counteract these forces, additional counterweights are added on the opposite end, from the piston, to cancel out the vibrations. It is called Counterbalancing.

Look at the Graph, it indicates the primary forces produced by the motion of a single cylinder engine. The first and second half along the horizontal axis indicates two unbalanced forces, now these forces create vibrations when the piston moves. If we see the structure of a piston and Conrod, it is heavy at the top and light at the bottom, this creates an imbalance when the piston moves up and down. To counteract these forces, additional counterweights are added on the opposite end, from the piston, to cancel out the vibrations. It is called Counterbalancing.Reduce the age-old flex:

Another set of vibrations which emerging from the engine are actually coming from the flexing of the unbalanced crankshaft. The 350 cc engine has 2 bearings on the left side and only one on the right side. The current arrangement results in flexing of the crankshaft on the right side. A solution for this is devised by Paul Carberry, of Carberry Motorcycles, in the form of a Vibration reduction plate. It balances the uneven distribution of mass around the axis thus preventing the crankshaft from flexing. Note that the Vibration due to the Crankshaft occurred only at higher RPM’s so primary vibrations (Emerging from the cylinder) on a standstill, remain unaffected by the plate.

Another set of vibrations which emerging from the engine are actually coming from the flexing of the unbalanced crankshaft. The 350 cc engine has 2 bearings on the left side and only one on the right side. The current arrangement results in flexing of the crankshaft on the right side. A solution for this is devised by Paul Carberry, of Carberry Motorcycles, in the form of a Vibration reduction plate. It balances the uneven distribution of mass around the axis thus preventing the crankshaft from flexing. Note that the Vibration due to the Crankshaft occurred only at higher RPM’s so primary vibrations (Emerging from the cylinder) on a standstill, remain unaffected by the plate.Add some rubber to it:

The engine is a stressed member of the frame meaning it is a part of the structural integrity of the frame. You can check it yourself by following the frame pipe coming down from the steering head. If the engine is a stressed member then that pipe will end where the engine begins. Another point is that most of the parts resting on the frame are made of metal. Meaning if the engine vibrates, then the metal components vibrate because metal tends to resonate. To solve the problem, the frame can be redesigned to enclose the engine and it can be attached to the frame via a number of rubber mounts. Note that these rubber mounts also tend to lose their dampening ability over time so it’s better to make them out of Polyurethane or other similar material.

The engine is a stressed member of the frame meaning it is a part of the structural integrity of the frame. You can check it yourself by following the frame pipe coming down from the steering head. If the engine is a stressed member then that pipe will end where the engine begins. Another point is that most of the parts resting on the frame are made of metal. Meaning if the engine vibrates, then the metal components vibrate because metal tends to resonate. To solve the problem, the frame can be redesigned to enclose the engine and it can be attached to the frame via a number of rubber mounts. Note that these rubber mounts also tend to lose their dampening ability over time so it’s better to make them out of Polyurethane or other similar material.Another thing which Royal Enfield has done with their LS-410, which they use in Himalayan, is to make it with just 3 pieces.

So upon successfully doing these methods, we can reduce the infamous vibrations of the LS-349 UC Engine of Royal Enfield motorcycles.

By: Yetnesh Dubey