We all know that the revolutionary 4 stroke engine is the successor of the 2 stroke engine. The 2 stroke engine is still known for the tremendous amount of power and punch the engine produces. But the engine had many emissions problems, producing a lot of unwanted gasses that can easily damage the environment. The engine can produce so much power that most of the 2 stroke motorcycles can just eat up the current 4 stroke motorcycles in most of the factors.

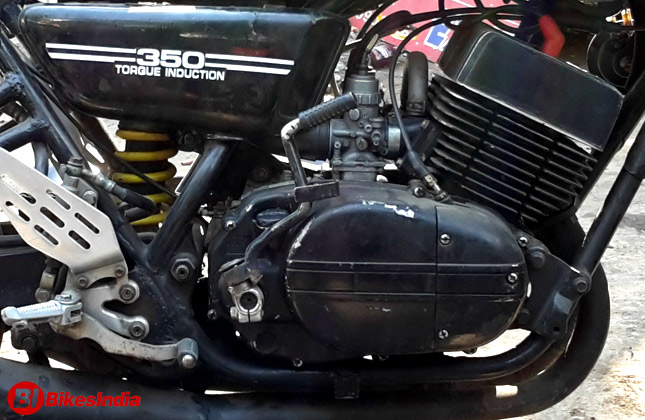

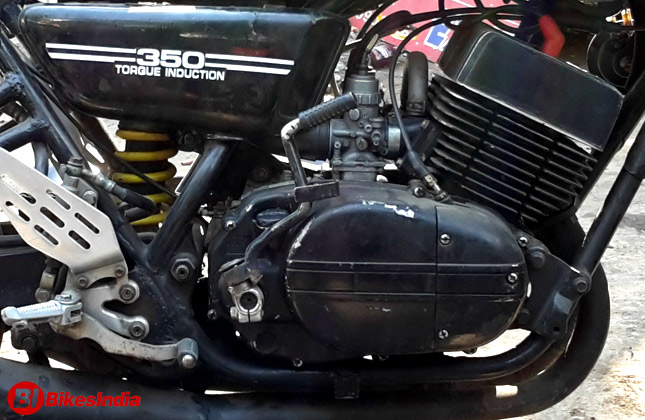

One of the most revolutionary stroke engine motorcycles still wanted to be riders of the present day are the Yamaha's RX100 and the RD350. These motorcycles still have so much demand today, riders are even ready to pay an inexpensive premium price for the motorcycles. We were lucky enough to find the cross section of a 2 stroke engine so that we can help our readers understand how the engine works. So let's find out.

One of the most revolutionary stroke engine motorcycles still wanted to be riders of the present day are the Yamaha's RX100 and the RD350. These motorcycles still have so much demand today, riders are even ready to pay an inexpensive premium price for the motorcycles. We were lucky enough to find the cross section of a 2 stroke engine so that we can help our readers understand how the engine works. So let's find out.

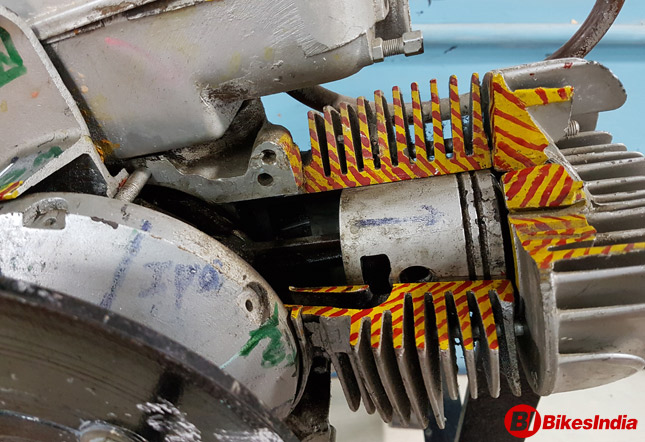

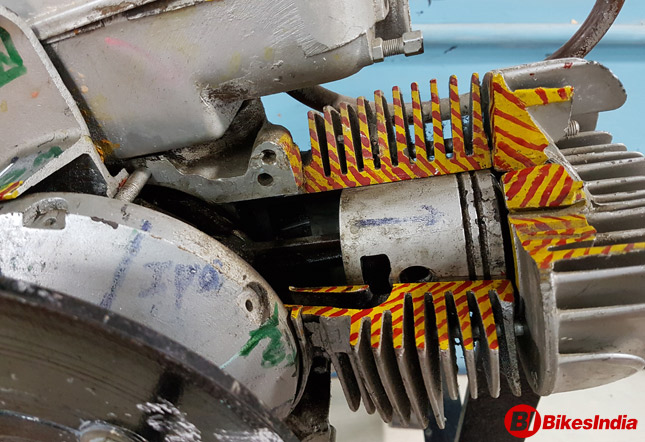

The 2 stroke engine is a type of Internal combustion engine where one power cycle is completed with two strokes of the piston during only one rotation of the crankshaft. The 2 stroke engine performs all the same steps which are performed by 4 stroke engine – suction, compression, expansion & exhaust, but the 2 stroke engine performs all these steps in only 2 stroke, unlike the 4 stroke engine which completes one power cycle in 4 strokes.

RELATED ARTICLE: 4-Stroke Petrol Engine Working Explained

Parts of 2-stroke engine:

Working of 2 stroke Engine

Working of 2 stroke Engine

At first, the Piston is moved from TDC to BDC to let the fresh air enter the combustion chamber. The fresh Air-Fuel mixture gets into the combustion chamber through the crankcase.

The Piston is pushed up from BDC to TDC. The fuel-air mixture gets compressed & spark plug ignites the mixture. As the mixture gets expanded, the Piston moves down. During upstroke, the inlet port is opened. While the inlet port is opened, the mixture gets sucked inside the crankcase. When the mixture is pushed up into the combustion chamber during the previous up stroke, a partial vacuum is created as no mixture is left behind in the crankcase. This mixture is ready to go into the combustion chamber during down stroke but remains in the crankcase until the piston goes up till TDC.

From the next down stroke, the exhaust gasses get expelled out from one side while a fresh mixture enters the combustion chamber simultaneously due to partial vacuum created in the combustion chamber after removal of exhaust gasses.

By: Rishath Suresh

One of the most revolutionary stroke engine motorcycles still wanted to be riders of the present day are the Yamaha's RX100 and the RD350. These motorcycles still have so much demand today, riders are even ready to pay an inexpensive premium price for the motorcycles. We were lucky enough to find the cross section of a 2 stroke engine so that we can help our readers understand how the engine works. So let's find out.

One of the most revolutionary stroke engine motorcycles still wanted to be riders of the present day are the Yamaha's RX100 and the RD350. These motorcycles still have so much demand today, riders are even ready to pay an inexpensive premium price for the motorcycles. We were lucky enough to find the cross section of a 2 stroke engine so that we can help our readers understand how the engine works. So let's find out.The 2 stroke engine is a type of Internal combustion engine where one power cycle is completed with two strokes of the piston during only one rotation of the crankshaft. The 2 stroke engine performs all the same steps which are performed by 4 stroke engine – suction, compression, expansion & exhaust, but the 2 stroke engine performs all these steps in only 2 stroke, unlike the 4 stroke engine which completes one power cycle in 4 strokes.

RELATED ARTICLE: 4-Stroke Petrol Engine Working Explained

Parts of 2-stroke engine:

Piston–

In an engine, the piston is used to transfer the expanding force of gasses to mechanical rotation of crankshaft via a connecting rod. The piston is able to do this because it is secured tightly within cylinder using piston rings to minimize the clearance between cylinder and piston. Clearance is provided in order to avoid the piston from getting jammed and in order to reduce friction levels.

Crankshaft–

A crankshaft is a part which converts reciprocating motion to rotational motion.

Connecting Rod–

A Connecting Rod transfers motion from the Piston to Crankshaft which acts as a lever arm.

Counterweight–

Counterweight on the Crankshaft is used to reduce the vibrations due to imbalances produced in the rotating assembly.

Flywheel–

Flywheel is a rotating mechanical device which is used to store energy.

Inlet & Outlet Ports–

It allows the entry of the air-fuel mixture and allows the burnt or exhaust gasses to exit. Please note that ports are used in 2 stroke engines and valves are used in 4 stroke engines.

Spark Plug–

A spark plug delivers electric current to the combustion chamber which ignites the air-fuel mixture leading to sudden expansion of gas that helps in the production of power.

In an engine, the piston is used to transfer the expanding force of gasses to mechanical rotation of crankshaft via a connecting rod. The piston is able to do this because it is secured tightly within cylinder using piston rings to minimize the clearance between cylinder and piston. Clearance is provided in order to avoid the piston from getting jammed and in order to reduce friction levels.

Crankshaft–

A crankshaft is a part which converts reciprocating motion to rotational motion.

Connecting Rod–

A Connecting Rod transfers motion from the Piston to Crankshaft which acts as a lever arm.

Counterweight–

Counterweight on the Crankshaft is used to reduce the vibrations due to imbalances produced in the rotating assembly.

Flywheel–

Flywheel is a rotating mechanical device which is used to store energy.

Inlet & Outlet Ports–

It allows the entry of the air-fuel mixture and allows the burnt or exhaust gasses to exit. Please note that ports are used in 2 stroke engines and valves are used in 4 stroke engines.

Spark Plug–

A spark plug delivers electric current to the combustion chamber which ignites the air-fuel mixture leading to sudden expansion of gas that helps in the production of power.

Working of 2 stroke Engine

Working of 2 stroke EngineAt first, the Piston is moved from TDC to BDC to let the fresh air enter the combustion chamber. The fresh Air-Fuel mixture gets into the combustion chamber through the crankcase.

The Piston is pushed up from BDC to TDC. The fuel-air mixture gets compressed & spark plug ignites the mixture. As the mixture gets expanded, the Piston moves down. During upstroke, the inlet port is opened. While the inlet port is opened, the mixture gets sucked inside the crankcase. When the mixture is pushed up into the combustion chamber during the previous up stroke, a partial vacuum is created as no mixture is left behind in the crankcase. This mixture is ready to go into the combustion chamber during down stroke but remains in the crankcase until the piston goes up till TDC.

From the next down stroke, the exhaust gasses get expelled out from one side while a fresh mixture enters the combustion chamber simultaneously due to partial vacuum created in the combustion chamber after removal of exhaust gasses.

By: Rishath Suresh