Shock absorbers are being one of the vital equipment in any vehicle responsible for stability and control. When we see the rear shock absorbers of any two wheelers, they are majorly categorized into two- Mono Shock and Dual Shock absorbers. In either of the two now a days “Gas Charged or Nitrox” dampers are commonly seen. You must be wondering what these dampers are and how good they are as compare to the regular spring loaded shock absorbers? Well, we will try to explain what these Gas Filled Dampers are and How they work in this article.

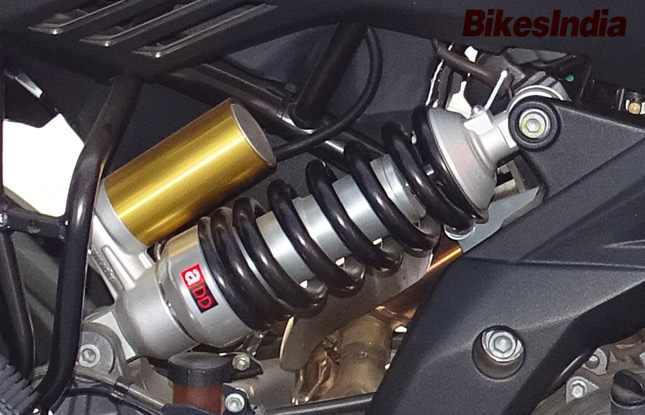

Shock absorbers are being one of the vital equipment in any vehicle responsible for stability and control. When we see the rear shock absorbers of any two wheelers, they are majorly categorized into two- Mono Shock and Dual Shock absorbers. In either of the two now a days “Gas Charged or Nitrox” dampers are commonly seen. You must be wondering what these dampers are and how good they are as compare to the regular spring loaded shock absorbers? Well, we will try to explain what these Gas Filled Dampers are and How they work in this article.The gas filled shock-ups can be easily differentiated by ‘Canister’ attached to the conventional spring loaded shock absorber. It is this Canister which holds the gas inside, it is mostly Nitrogen gas used in these cans and that is the reason why it is also known as ‘Nitrox’ dampers. Before we go ahead with the details of the topic it is mandatory to check how a shock absorber (conventional) works-

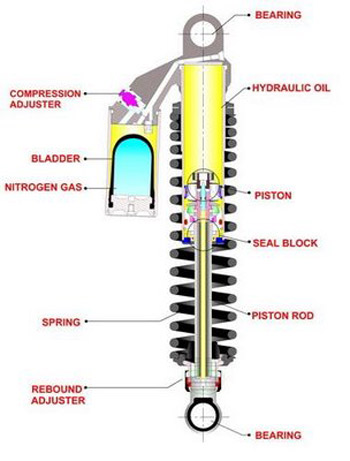

A regular spring loaded damper normally has:

1) Spring

2) Body or Tubes

3) Piston

4) Valves and

5) Damping Oil.

The job of the spring is to bounce back from the uneven surface rather than soaking the impact, it is the Piston along with the Oil responsible for the damping action. So, when the vehicle hits a bump, the piston inside the damper moves within the tube filled with damping oil along with perforated Valves. The oil is then dissipates from the holes of the valve and hence allowed limited resistance to the movement of piston thereby performing efficient damping.

2) Body or Tubes

3) Piston

4) Valves and

5) Damping Oil.

This up and down movement of piston inside the oil filled tube caused a phenomenon called ‘Cavitation’ in the damping oil- in simple words; it is foaming of the oil. What happens when there is excessive movement takes place, the gas molecules present in the oil (which is about 10%) start releasing due to loosening of the bond between the oil molecules and the gas molecule present in the damping oil, resulting the formation of air bubbles which eventually takes the form of Foam.

This up and down movement of piston inside the oil filled tube caused a phenomenon called ‘Cavitation’ in the damping oil- in simple words; it is foaming of the oil. What happens when there is excessive movement takes place, the gas molecules present in the oil (which is about 10%) start releasing due to loosening of the bond between the oil molecules and the gas molecule present in the damping oil, resulting the formation of air bubbles which eventually takes the form of Foam.The Cavitation of the oil normally takes place when you ride your vehicle for considerably long time, due to this the performance of the damper reduces and you can experience the drop in the efficiency of the shock absorber over the period of long journey. However, the foaming of the oil gets rectified once the oil gets settled after the end of ride and there the efficiency of the damper also gets back to its normal. But anyway it is a shortcoming of the oil filled spring loaded shock absorbers, now to overcome this shortfall here come the ‘Gas Filled or Nitrox Charged’ dampers.

READ ALSO: Monoshock Suspension Vs Dual Shocks

These Gas/Nitrox filled dampers are used to prevent foaming of the damping oil, so that the efficiency of the shock absorber remains constant throughout. The canister is used to be filled with pressurized Nitrogen gas, which further act as reservoir for both oil and Nitrogen gas. The role of the Nitrogen gas is to keep the damping oil pressurized so that the gas molecules present in the oil remain bonded with the oil molecules and must not get loosen to form bubbles/foam and hence prevent the Cavitation.

This is how the piggyback canister attached to the rear shock absorber (Mono-shock/Dual-shocks) of your ride helps maintaining the efficiency of the damper throughout the ride irrespective of the riding condition. So, folks when you see these Nitrox filled shock absorbers featured on your motorcycle, feel privileged as they are indeed a better technology and meant for rendering an improved riding experience for you.

By: Farhan Kashif