Before we go into the details of floating disc brakes, I would like to tell you to not get Floating Disc Brakes confused with Floating Calipers, both are different parts. We will talk about Floating Disc/Rotors here and leave “Floating Caliper” a topic for another time.

Before we go into the details of floating disc brakes, I would like to tell you to not get Floating Disc Brakes confused with Floating Calipers, both are different parts. We will talk about Floating Disc/Rotors here and leave “Floating Caliper” a topic for another time.What Do They Look Like?

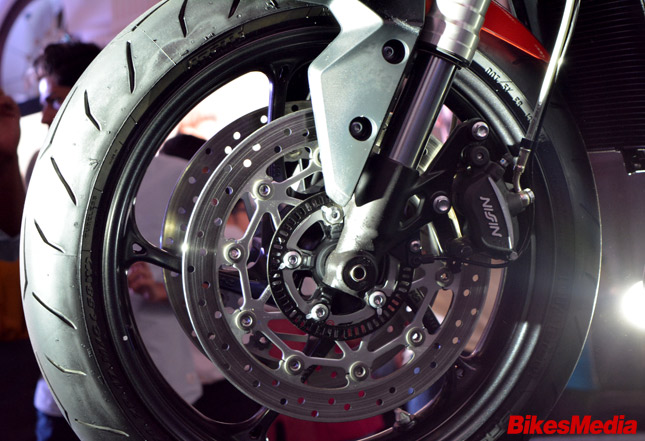

A Floating Disc is a two piece rotor; they consist of a steel outer part which is riveted to an aluminum center part which is fixed onto the motorcycle wheel. The steel part is the place where the brakes pads brush on and the aluminum part is the one which connects the wheel and the steel. When brakes are applied then the rivet allows float and movement between the two which brings the bike to a stop.

This bad boy goes by the name of “T- drive” and is developed by Brembo in accordance to their experience in MotoGP and SBK. Aside from the usual spec talk this too does the same job of any normal floating disc brake but only better.

This bad boy goes by the name of “T- drive” and is developed by Brembo in accordance to their experience in MotoGP and SBK. Aside from the usual spec talk this too does the same job of any normal floating disc brake but only better.The outer part of floating discs are made up of several different other materials like aluminum, different alloys of titanium, carbon, cast iron and of course stainless steel but mostly we prefer aluminum and steel one because of their high mechanical strength, cheap rates and over all versatility. The use of carbon floating disc brakes is limited to the track only and the cast iron one is rarely or not used at all in today’s bikes because comparatively, it breaks easily.

Advantages Of Floating Disc Brakes:

Consider a normal braking scenario the bike is going to 70 km/hr, the rider applies the brakes. The fluid flows from the master cylinder into the pistons in the caliper which pushes the brake pads onto the wheels causing friction, this friction is turned into heat thus with this expense, the bike comes to a halt. When the heat is generated the rotor tends to expand and when it’s effectively air cooled, it contracts. Now the problem is the rotor can take all that expansion and contraction up to a limit only.

So consider another scenario, where the rotor is pushed hard and heated under harsh riding conditions so it expands; by allowing it to float away from the wheel while it’s riveted with the inner spider (aluminum part) structure. In this way, it becomes easier for the rotor to contract and expand without being constrained by its mounting on the wheel. The ability to expand freely in any direction prevents the rotor from warping.

So consider another scenario, where the rotor is pushed hard and heated under harsh riding conditions so it expands; by allowing it to float away from the wheel while it’s riveted with the inner spider (aluminum part) structure. In this way, it becomes easier for the rotor to contract and expand without being constrained by its mounting on the wheel. The ability to expand freely in any direction prevents the rotor from warping.RELATED ARTICLE: Why Disc Brakes Are Better Than Drum Brakes?

What warping means is that after a long continuous expansion and contraction of the disc or when the disc exceeds its maximum temperature; then the contraction will not bring back the original shape of the steel which means the disc’s surface will become uneven, rendering the disc useless.

RELATED ARTICLE: How Motorcycle Disc Brakes Work

Although all you folks don’t need to start throwing away the front disc on your Pulsar 220 or Apache 200 because floating discs are not the only way to prevent the disc from warping. A thick rotor between the ranges of 4.5 to 6 mm can easily take on all the action you throw on it. To give a little perspective a 5.5mm thick rotor of a good quality material can be easily used as the front rotor on a super sport.

In The End:

"Should we really worry about the absence of floating disc brakes on your bikes?" Provided you do occasional track days and also a quite a lot of touring. The answer is no. The answer will be the same if we ask “do we really need two turbos on a Kawasaki H2?” which is a complete road legal bike. A rotor thick enough and of a good quality can get the job done easily. So the real question is, "do you just want the job to be over?" or "do you want to get that promotion you have had your eyes on for quite a while?". The answer as I said will bring you one step closer to peace.

For all the awesome things about bikes stay tuned to BikesMedia.

By: Yetnesh Dubey