We all must have heard the term “Dyno”. The thing is, Dyno is nothing but a short for a Dynamo-meter, because well, the name is too big to say it every single time we refer to it. But the importance that a Dyno holds for the overall development of any bike is something we cannot really ignore. Every single bike that is manufactured and brought on the road is tested on a dyno at some point of time in its production cycle.

We all must have heard the term “Dyno”. The thing is, Dyno is nothing but a short for a Dynamo-meter, because well, the name is too big to say it every single time we refer to it. But the importance that a Dyno holds for the overall development of any bike is something we cannot really ignore. Every single bike that is manufactured and brought on the road is tested on a dyno at some point of time in its production cycle. If only bikes could talk, there would be just so many dyno stories to be heard about. Also to give you a small piece of information, all the numbers that we read about on the spec sheet, the power, torque, and stuff; where do you think the information comes from. Not like the motorbikes can boast about the power they make. It all needs to be calculated over a machine of some sorts, and that my dear friends, is done using a Dyno.

Now Dynos come in two types as follows:

1. Absorption or Passive Dynamo meter

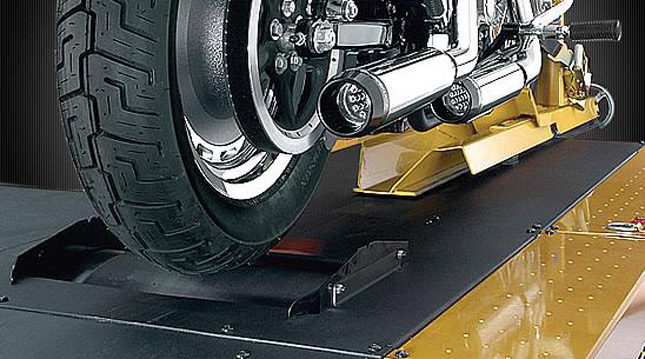

This is the kind of dyno that is used to record the performance of the bike. As the name suggests, this dyno needs working upon, i.e. you need to apply force on it to make it work. So the bike actually needs to be working to rotate the dyno wheels and that is how the data is recorded. The working of this dyno is simple. You perch the bike on it and let it rip. The dyno calculates the amount of power transmitted to the rear wheel depending on the force exerted, and the wheel speed achieved on the dyno; simple. In case the power made by the engine needs to be calculated, that is a completely difference dyno required for it which is a lot more complicated and uses more specialized electronics on it.

READ ALSO: How Realistic The Certified Mileage Figures Are?

2. Universal or Active Dynamometer:

Now this is a fun dyno. The main purpose of this dyno is to test the rigidity and to take stress test of the bike. Here the bike is not needed to be working but the dyno works on the bike. The dyno works on its power and moves the bike parts to check for how much stress the bike can hold. The moving parts of the bike are checked for stress and rigidity and hence the loading amount and everything else is checked and certified. In case of a custom built motorcycle, this is an importance test by performing simulated real time testing conditions to check if the motorbike is safe to be ridden on the road.

This is the kind of dyno that is used to record the performance of the bike. As the name suggests, this dyno needs working upon, i.e. you need to apply force on it to make it work. So the bike actually needs to be working to rotate the dyno wheels and that is how the data is recorded. The working of this dyno is simple. You perch the bike on it and let it rip. The dyno calculates the amount of power transmitted to the rear wheel depending on the force exerted, and the wheel speed achieved on the dyno; simple. In case the power made by the engine needs to be calculated, that is a completely difference dyno required for it which is a lot more complicated and uses more specialized electronics on it.

READ ALSO: How Realistic The Certified Mileage Figures Are?

2. Universal or Active Dynamometer:

Now this is a fun dyno. The main purpose of this dyno is to test the rigidity and to take stress test of the bike. Here the bike is not needed to be working but the dyno works on the bike. The dyno works on its power and moves the bike parts to check for how much stress the bike can hold. The moving parts of the bike are checked for stress and rigidity and hence the loading amount and everything else is checked and certified. In case of a custom built motorcycle, this is an importance test by performing simulated real time testing conditions to check if the motorbike is safe to be ridden on the road.

Importance of Dynamo-meter in Engine Tuning

Importance of Dynamo-meter in Engine TuningNow, the need for engine tuning is important to drain the maximum amount of power from the engine. The most efficient engine is the one which can make the most amount of power in the least amount of fuel. Though this is tough to achieve, engineers work on making the engine the most powerful along with the most fuel efficient as possible. The ability to meet the perfect balance of power and efficiency is important and that is where the dyno testing comes in.

In a dyno test, the engineers run the bike to check out the amount of power the engine makes and the amount of power that is transmitted to the rear wheel. In an ideal situation, the power to the rear wheel should be exactly the same as the power made at the engine. But we know that due to the transmission loss present, the amount is less. Hence, the engineers then work on maximizing the power delivered to the rear wheels by trying multiple different combinations and yet keep an eye out on the efficiency figures of the bike. After a lot of permutations and combinations, the engineers are able to find the right balance of optimum power and efficiency and this is made possible only on the dyno.

READ ALSO: How Carburetor And Fuel Injection Differ In Various Conditions

Also, when a bike is being serviced and the engine needs tuning, the dyno is what helps them find the sweet spot once again. The bike is run on the dyno and the results are checked while the engine is tuned to meet the correct specifications and that is when the bike has been properly tuned. So make sure that when the bike is ill-performing, it is a good idea to get it on a dyno and check what it is lacking. I know it is a bit hard to find a dyno somewhere in India but most service centers of companies are mandated to have a dyno on the premises and if they do have it, it is a good idea to take it for a spin on it.

By: Pratik Patole