The Drive Chain also known as Final Drive Chain is the ultimate part of any motorcycle responsible to transmit the energy/ power of engine to the rear wheel. The drive chain is actually an integral and penultimate part of the complex Drive Train of any engine which is comprised of Transmission Gears, Primary Drive and Final Drive.

The Drive Chain also known as Final Drive Chain is the ultimate part of any motorcycle responsible to transmit the energy/ power of engine to the rear wheel. The drive chain is actually an integral and penultimate part of the complex Drive Train of any engine which is comprised of Transmission Gears, Primary Drive and Final Drive. Final Drive:

The Final Drive for any engine is the component responsible for transferring engine movement to the rear wheel of the bike. The Final Drive can be broadly categorized into three depending upon the physical composition of the component:

- Drive Shaft

- Drive Belt

- Drive Chain

Drive Chain:

Drive Chain:The drive chain is the most common, cost effective and easy to maintain Final drive, it is actually one of the primitive form of final drive still in use since the invention of Bi cycles. The drive chains are mainly divided into three categories:

- Standard Roller Chains

- O- Ring Chains

- X- Ring Chains

Standard Roller Chains:

Standard Roller Chains:The Standard non O-Ring chains are the regular drive chains that we use in our older motorcycles and in some of our latest small capacity motorbikes. The standard roller chains are also non self lubricating chains and hence it is required to lubricate them externally on regular basis.

Even lubricating the non O ring standard chains are not sufficient as sometimes it is hard to lubricate the internal parts of the chain and if by putting extra effort and extra lubricants to the chain you succeed in lubricating it "properly" soon the dust and filth attracts to the lubricated chain including its internal parts make it difficult to clean and lubricate it for the next time.

The filth deposited inside the chain components not only corrodes the drive chain but also acts responsible for wear and tear of sprockets and chain itself.

O-Ring Chains:

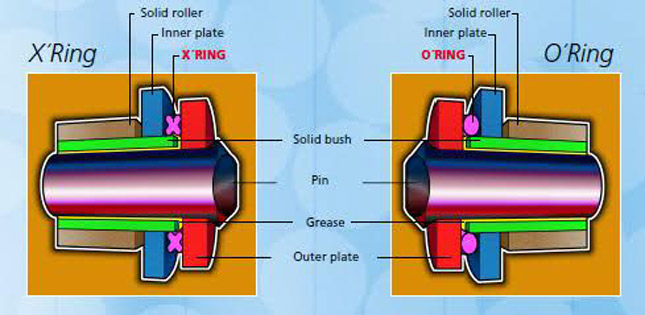

O-Ring Chains:The O-Ring Chains are the modern drive chains consists of a rubber "O- Ring" placed between the chain plates. These O-Rings are fitted in between chain plates to seal the already vacuum filled grease between the rollers and the other internal components of chain. This mechanism of O-Ring type chains make them self lubricated and hence they require less maintenance and have longer life and better performance in longer run.

In O-ring type chains when the rubber "O- Ring" is pressed and riveted, it changes shape and becomes flat from the sides hence seals the space efficiently but the pressed O-Ring with flat sides create friction which results into significant drag. This drag can be felt while rolling the rear wheel in cold state, however the drag vanishes after the chain rotates few turns and heats up.

X- Ring Chains:

The X- Ring Chains as the name suggests are drive chains with "X" shape rubber ring used instead of "O" shape. The X- Ring type chains are more modern chains with X-shaped rubber ring placed in between the chain plates to seal the grease filled inside the chain components. As upon pressing these type of rings come in contact with lesser surface area and hence less drag coefficient is generated with same efficient sealing property as O-Ring chains provide.

Advantages And Disadvantages Of Standard Non O-ring Chains Vs O-Ring/ X Ring Chains:

Advantages:

O-Ring/ X Ring Chains:

Standard Non O-Ring Chain:

- Easy to maintain

- Longer life

- Less Sprocket wear and tear

- Limited or no chain stretching

- Limited or no tightening is required

Standard Non O-Ring Chain:

- Relatively Cheaper

Disadvantages:

Standard Non O-Ring Chain:

O-Ring/ X Ring Chains:

- Difficult to maintain

- Less Efficient

- Lesser Life

- High Sprocket wear and tear

- Regular Tightening is required

O-Ring/ X Ring Chains:

- Little Expensive

- Negligible Drag

As O-Ring/ X Ring Chains are self lubricating they require less maintenance but with little complex construction it is needed to take good care of it while cleaning. There are rubber O/X rings are placed in the chain and are vulnerable to damage when treated with strong solvents like petrol or any other organic compounds. Therefore it is necessary to clean your O-Ring/ X Ring Chains with only recommended Chain Cleaner.

We will cover the cleaning of the O-Ring/ X Ring Chains in our upcoming topic; "How To Clean And Maintain The Drive Chains", till then stay tuned.

By: Farhan Kashif