With new technology hitting the motor biking scene, one can see a lot of new innovations coming up to improve the performance and efficiency of motorcycles. Though even with all this, the basics of the motorcycle; i.e. the engine, clutch and gear will always remain the same. Or will it? This is actually a million dollar question everyone is asking about. But we are not going to discuss about all those things; rather we have a much interesting topic in hand here. Gearbox technologies have developed in motorcycles since quite some time and today there are two widely used gearboxes in motorcycles and that is Constant Mesh type gearbox and Claw Shifted gearbox.

With new technology hitting the motor biking scene, one can see a lot of new innovations coming up to improve the performance and efficiency of motorcycles. Though even with all this, the basics of the motorcycle; i.e. the engine, clutch and gear will always remain the same. Or will it? This is actually a million dollar question everyone is asking about. But we are not going to discuss about all those things; rather we have a much interesting topic in hand here. Gearbox technologies have developed in motorcycles since quite some time and today there are two widely used gearboxes in motorcycles and that is Constant Mesh type gearbox and Claw Shifted gearbox.

Constant Mesh Gearbox:

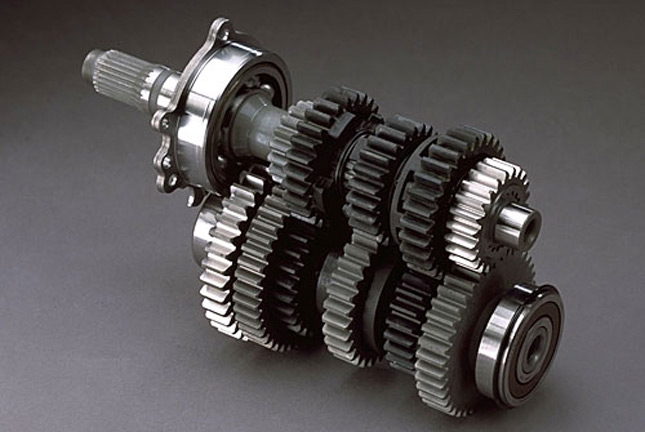

Constant Mesh Gearbox:In a constant mesh gearbox, the gear claws are all arranged on a single file but the order is jumbled up. So for instance the first gear is located at the far end next to the sixth gear and the third gear after that and so on. The reason behind this is to allow for easy access for the drivetrain accessing the gear cogs on that particular gear. If we check out the actual gearbox mechanism, we can find that the gears are connected to a patterned cylinder connected to shifters. So when the gear is shifted, the patterned cylinder moves which moves the shifter and slots the gear cog in the drivetrain one that has the control. This way the gears are engaged and disengaged depending upon the input given. But in practicality all the gear cogs are moving and are not static like they are in cars.

Claw Shifted Gearbox:

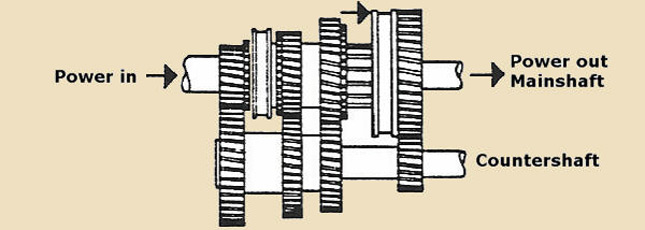

Claw Shifted Gearbox:In a Claw Shifted Gearbox the gear cogs are all freely moving and not connected to each other in any ways. When the gear is shifted, an electrically rotating countershaft moves the freely rotating claw to move the cog and slots it into the perfect gear to provide power to the rear wheel. The main thing here is that since the gears are not interconnected, they are in a static position if they are not working and not moving unlike in Constant Mesh Gearbox. The advantage that Claw Shifted Gearbox has here is that since the cogs are not moving, when the gear is slotted in, there is almost no friction that takes place. Hence the gear shifts are smooth and accurate without any slippages.

Which one is better?

This is the real question here actually, but in theory both are equally good in their own right. The only basic thing to consider here is that both have their own flip-sides.

Constant Mesh- In case of Constant Mesh Gearboxes they are pretty cheap to make and install and servicing them is also an easy affair since they are all connected in a single file next to each other and all keep moving together at the same time. Just the problem comes sometimes when slotting the gear in place because since the slotting happens in movement there are chances of slippages due to the extreme friction in place. The best part here is that there is no absolute failure in this case.

Claw Shifted- In case of Claw Shifted Gearbox, the gear shits are smooth and accurate, but the problem occurs if the cogs are not properly lubricated which could cause some amount of friction. Also since the entire system is electrically controlled, if the unit fails, then the entire gear system goes for a toss. And if that was not enough, since the gear shifting is sequential, of one of the gears falter, then again the entire system goes in for a toss. Though things are not again as foolproof with Constant Mesh as well, but at least these problems don’t occur there.

So yes, there are advantages and disadvantages of all, but the cost factor also comes into play and this is where it all boils down to. Constant Mesh is a relatively cheap option to go for and hence is used in most of the bikes we see playing on the road, but in case of premium or superbikes, Claw Shifted Mechanism is a more suited one because the bikes are running on a very high RPM and the Constant Mesh is not capable to handle that kind of stress in gear shifts.

By: Pratik Patole