The final drive on a motorcycle is the connection between the output shaft of the gearbox and the rear wheel. In scooters the engine is located at the rear, so that a simple gear train is used to put the power onto the rear wheels. In case of motorcycles, the distance between the output shaft and rear wheel is considerably higher. So it becomes necessary to adopt an appropriate drive which can transmit power and torque without much loss. The following are some types of final drives commonly used on motorcycles.

1. Belt Drive

This drive system includes a driving pulley, rubber belt and a driven pulley for the power transmission. The rubber belts have teeth on the contact side of the belt. As there are grooves provided on the driven and driver pulleys, the grooves on the belt matches them. The driver pulley is attached on the output shaft of the gearbox while the driven pulley is mounted onto the rear wheel. The rubber belt sits between both the pulleys and transmits power.

READ ALSO: Motorcycle Chain Vs Belt Drive System

The belt is generally made with polychloroprene rubber along with metallic torsion cords inserted in the middle, to increase its tensile strength. A nylon coating on the upper surface of the belt protects it from cracking. A belt with either a crack or a broken teeth should be replaced immediately.The major benefit of belt drive is that, it doesn't require any lubricating maintenance or adjustment for its life. But the life of these belts are comparatively lower, and requires frequent replacement due to wear and tear. The Belt drives can be found in abundance in Cruisers, as they are made for munching miles without any hindrance. 2. Chain Drive

2. Chain Drive

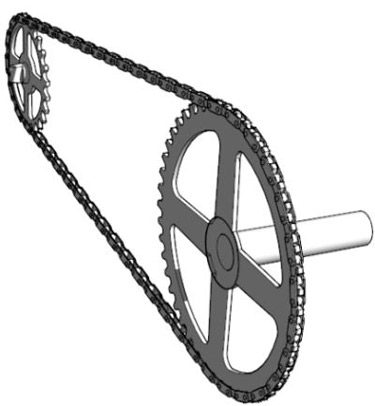

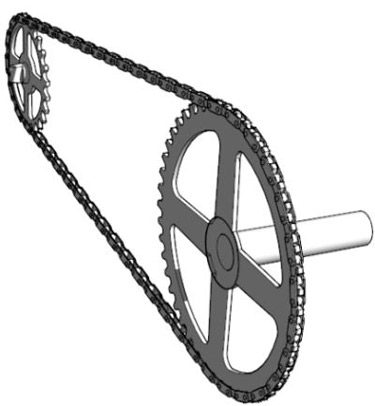

The chain drive is the most used and most straightforward way of getting power transmitted to the rear wheel. The chain drive is also very light in weight. Most of the motorcycles make use of this type of drive, due to its very high efficiency. It works at almost 99% efficiency, where the remaining 1% is lost due to friction. The chain drive has two sprockets attached at the output shaft of the gearbox and the rear wheel, with the chain connecting both. The sprockets are made up of hardened steel and generally has 12 to 23 teeth on the front, and 30 to 72 teeth at the rear. The chain comes in different types according to the requirements, say O ring, X ring.

The length of the chain increases with time, which creates noise during operation and also lowers the efficiency. Appropriate maintenance is required for efficient working of the chain drive. Cleaning and lubrication at regular intervals is required to reduce wear and tear. The swingarm facilitates a slot for the backward movement of the rear wheel assembly, up to an acceptable length. The chain drive is most vastly used in commuter and sports bikes, due to its very high efficiency.

3. Shaft Drive

A few larger motorcycles eliminate the chain problems by incorporating a driveshaft from the engine through an universal joint to a spiral bevel gear on the rear wheel hub. The shaft at the rear operates in the oil bath and virtually requires no service or maintenance. Though the shaft drive is expensive to manufacture, it is smooth, quiet and trouble free. It consists of a drive shaft, universal joint, bevel gear joint and a casing.

The drive shaft are mostly hollow for better whirling protection at high speed. It's made up of mild steel without any stress concentration. The drive shaft is powered by the gearbox followed by a bevel gear pair to the rear wheel. These parts are covered in a casing which acts as a sump for lubricating oil. The same case is also used as an integral part of the swingarm. Since the production cost is on the higher side, this is the least used type on motorcycles. The shaft drives are mostly used on Adventure and sports tourer motorcycles.

By: Aravind Rb

*** Belt Drive at Harley Davidson

1. Belt Drive

This drive system includes a driving pulley, rubber belt and a driven pulley for the power transmission. The rubber belts have teeth on the contact side of the belt. As there are grooves provided on the driven and driver pulleys, the grooves on the belt matches them. The driver pulley is attached on the output shaft of the gearbox while the driven pulley is mounted onto the rear wheel. The rubber belt sits between both the pulleys and transmits power.

READ ALSO: Motorcycle Chain Vs Belt Drive System

The belt is generally made with polychloroprene rubber along with metallic torsion cords inserted in the middle, to increase its tensile strength. A nylon coating on the upper surface of the belt protects it from cracking. A belt with either a crack or a broken teeth should be replaced immediately.The major benefit of belt drive is that, it doesn't require any lubricating maintenance or adjustment for its life. But the life of these belts are comparatively lower, and requires frequent replacement due to wear and tear. The Belt drives can be found in abundance in Cruisers, as they are made for munching miles without any hindrance.

2. Chain Drive

2. Chain Drive The chain drive is the most used and most straightforward way of getting power transmitted to the rear wheel. The chain drive is also very light in weight. Most of the motorcycles make use of this type of drive, due to its very high efficiency. It works at almost 99% efficiency, where the remaining 1% is lost due to friction. The chain drive has two sprockets attached at the output shaft of the gearbox and the rear wheel, with the chain connecting both. The sprockets are made up of hardened steel and generally has 12 to 23 teeth on the front, and 30 to 72 teeth at the rear. The chain comes in different types according to the requirements, say O ring, X ring.

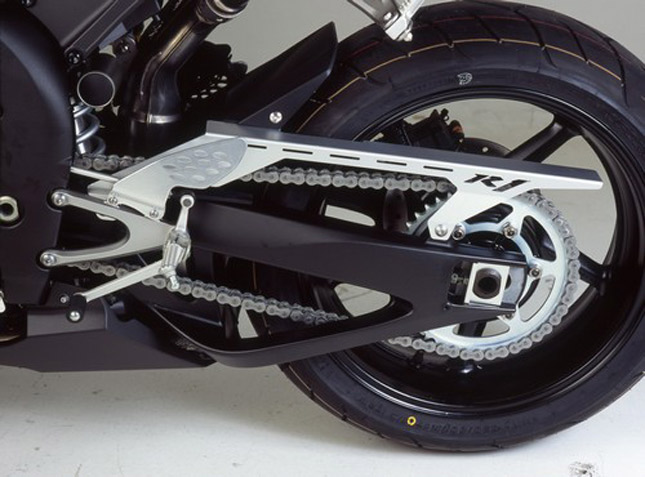

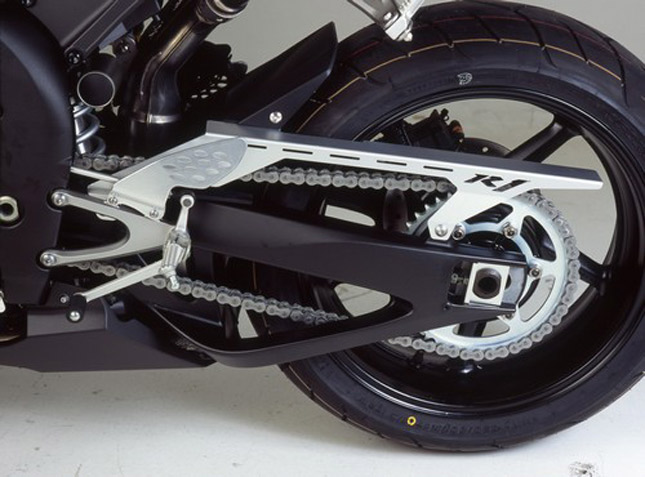

*** Chain drive on a Yamaha R1

The length of the chain increases with time, which creates noise during operation and also lowers the efficiency. Appropriate maintenance is required for efficient working of the chain drive. Cleaning and lubrication at regular intervals is required to reduce wear and tear. The swingarm facilitates a slot for the backward movement of the rear wheel assembly, up to an acceptable length. The chain drive is most vastly used in commuter and sports bikes, due to its very high efficiency.

3. Shaft Drive

A few larger motorcycles eliminate the chain problems by incorporating a driveshaft from the engine through an universal joint to a spiral bevel gear on the rear wheel hub. The shaft at the rear operates in the oil bath and virtually requires no service or maintenance. Though the shaft drive is expensive to manufacture, it is smooth, quiet and trouble free. It consists of a drive shaft, universal joint, bevel gear joint and a casing.

*** Shaft drive on a Honda VFR1200

The drive shaft are mostly hollow for better whirling protection at high speed. It's made up of mild steel without any stress concentration. The drive shaft is powered by the gearbox followed by a bevel gear pair to the rear wheel. These parts are covered in a casing which acts as a sump for lubricating oil. The same case is also used as an integral part of the swingarm. Since the production cost is on the higher side, this is the least used type on motorcycles. The shaft drives are mostly used on Adventure and sports tourer motorcycles.

By: Aravind Rb