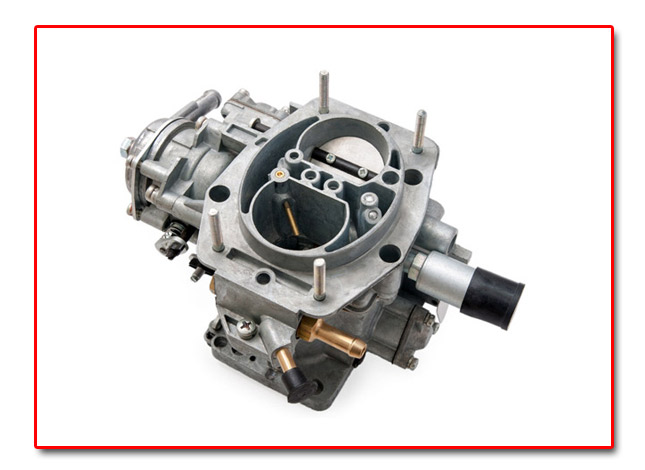

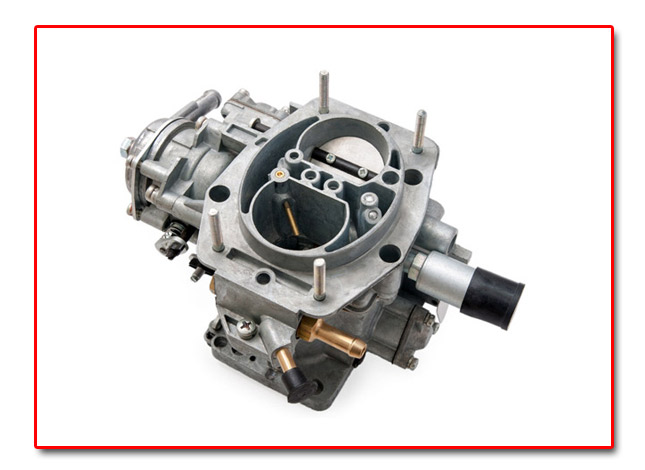

A petrol engine of any kind requires fuel and air mixture for effective combustion, which is a very well known fact. The process of creating this air-fuel mixture and regulating its flow is done by the Carburetors, whereas modern expensive machines make use of alternative electronic fuel injectors. The following article will explain about the basic principle, parts, working, advantages and disadvantages of a carburetor.

How does it work?

How does it work?

The basic principle involved in the working of a carburetor is "Bernoulli's Principle" which states: the faster air moves, the low its static pressure, and the higher its dynamic pressure. So basically, air exerted through a narrow path has more pressure compared to a wide path. In a carburetor, the fuel droplets are mixed with atmospheric air through a narrowed path, further leading to the intake valve of the engine.

RELATED ARTICLE: Carburetor Vs Fuel Injection- Motorcycle Fuel Systems

Parts of a Carburetor:

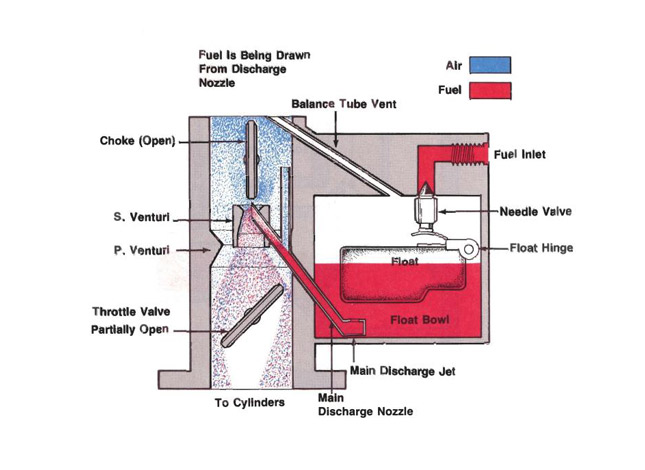

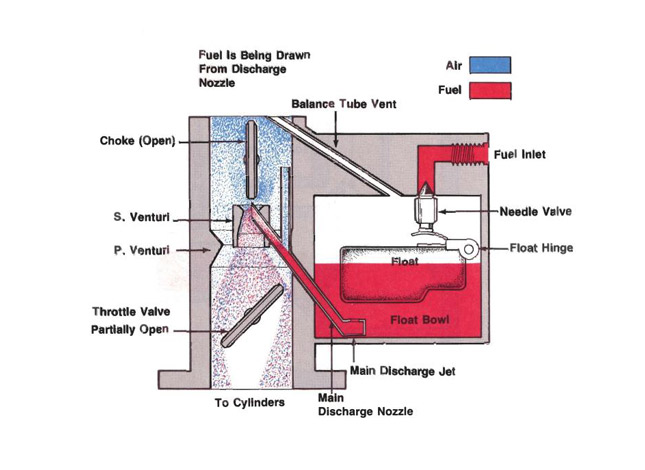

The most important part of a carburetor is a float chamber where the petrol from fuel tank is stored. There is a ball float valve inside the chamber that stops the petrol at a specified level, so that the carburetor doesn't over flow. The working of a ball float valve is the same technology as a toilet flush tank. The ball floats up and closes the valve when the petrol level reaches to the vantage point. On to the other side there is a unit comprising the Choke Valve, air nozzle, fuel discharge jet, Venturi, air-fuel mixture discharge nozzle and throttle valve. The Venturi narrows a bit and then widens again, to increase the air flow. Working:

Working:

The petrol from the float chamber enters the Venturi through a discharge jet. The atmospheric air passing through the air filter, enters the venturi from another side. The air enters the Venturi in a higher pressure thus breaking the petrol droplets into fine particles. This air-fuel mixture then flows to the throttle butterfly valve. The amount of mixture entering the engine is controlled by the throttle. When the throttle is fully closed, the engine would stall and come to a stop. To overcome this, an Idle system is used. Even when the throttle is fully closed a small amount of air-fuel mixture gets to the engine through an idle jet present just in front of the throttle butterfly valve. This mechanism prevents the engine from shutting off. Carburetor Tuning/Adjustments:

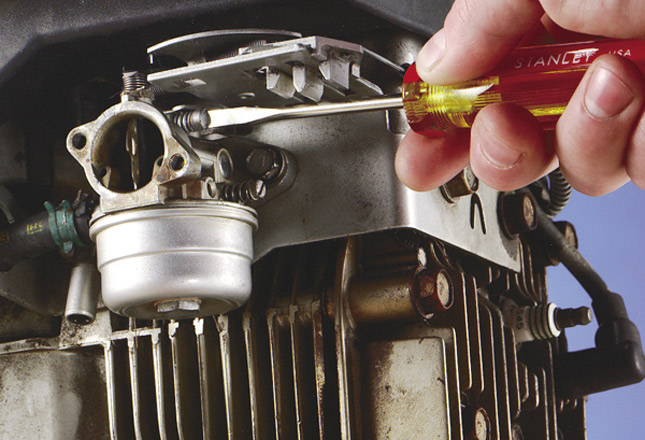

Carburetor Tuning/Adjustments:

The air-fuel mixture must be in a correct ratio for the engine to function seamlessly. A rich or lean mixture would lead to many problems including engine stalling, sudden switching off of engine or fuel efficiency issues. A "Rich Mixture" means more amount of petrol mixed with less amount of air. This would drop the efficiency significantly and also emit too much of carbon due to the unburnt fuel coming out together with the exhaust gases.

A "lean mixture" would be a vice versa, with more amount of air and less amount of fuel. This would make the engine stall and the throttle response delayed, sometimes even fail to start. To overcome these issues, the air and fuel valves must be tuned to perfection, for giving a perfect balance between performance and efficiency. During cold conditions the fuel doesn't vapourise as in normal conditions. During these situations, the engine needs a richer mixture to start. Thus, a choke valve is provided which restricts the amount of air entering the Venturi. This in turn creates a vacuum inside the carburetor drawing more amount of fuel in the venturi to make a rich mixture, making the engine operate seamlessly in cold temperatures.

Advantages and Disadvantages:

How does it work?

How does it work? The basic principle involved in the working of a carburetor is "Bernoulli's Principle" which states: the faster air moves, the low its static pressure, and the higher its dynamic pressure. So basically, air exerted through a narrow path has more pressure compared to a wide path. In a carburetor, the fuel droplets are mixed with atmospheric air through a narrowed path, further leading to the intake valve of the engine.

RELATED ARTICLE: Carburetor Vs Fuel Injection- Motorcycle Fuel Systems

Parts of a Carburetor:

The most important part of a carburetor is a float chamber where the petrol from fuel tank is stored. There is a ball float valve inside the chamber that stops the petrol at a specified level, so that the carburetor doesn't over flow. The working of a ball float valve is the same technology as a toilet flush tank. The ball floats up and closes the valve when the petrol level reaches to the vantage point. On to the other side there is a unit comprising the Choke Valve, air nozzle, fuel discharge jet, Venturi, air-fuel mixture discharge nozzle and throttle valve. The Venturi narrows a bit and then widens again, to increase the air flow.

Working:

Working: The petrol from the float chamber enters the Venturi through a discharge jet. The atmospheric air passing through the air filter, enters the venturi from another side. The air enters the Venturi in a higher pressure thus breaking the petrol droplets into fine particles. This air-fuel mixture then flows to the throttle butterfly valve. The amount of mixture entering the engine is controlled by the throttle. When the throttle is fully closed, the engine would stall and come to a stop. To overcome this, an Idle system is used. Even when the throttle is fully closed a small amount of air-fuel mixture gets to the engine through an idle jet present just in front of the throttle butterfly valve. This mechanism prevents the engine from shutting off.

Carburetor Tuning/Adjustments:

Carburetor Tuning/Adjustments: The air-fuel mixture must be in a correct ratio for the engine to function seamlessly. A rich or lean mixture would lead to many problems including engine stalling, sudden switching off of engine or fuel efficiency issues. A "Rich Mixture" means more amount of petrol mixed with less amount of air. This would drop the efficiency significantly and also emit too much of carbon due to the unburnt fuel coming out together with the exhaust gases.

A "lean mixture" would be a vice versa, with more amount of air and less amount of fuel. This would make the engine stall and the throttle response delayed, sometimes even fail to start. To overcome these issues, the air and fuel valves must be tuned to perfection, for giving a perfect balance between performance and efficiency. During cold conditions the fuel doesn't vapourise as in normal conditions. During these situations, the engine needs a richer mixture to start. Thus, a choke valve is provided which restricts the amount of air entering the Venturi. This in turn creates a vacuum inside the carburetor drawing more amount of fuel in the venturi to make a rich mixture, making the engine operate seamlessly in cold temperatures.

Advantages and Disadvantages:

Pros-

The main advantage is that, they are cheap to manufacture and maintain. This relatively means that carbureted motorcycles are cheaper to own and maintain compared to the fuel injected counterparts.

Cons-

1. They are very prone to cold start problems.

2. The working of a carburetor is highly affected by atmospheric pressure.

3. Throttle response is weak in a carbureted motorcycle.

4. Regular check ups and maintenance is required.

By: Aravind RB

The main advantage is that, they are cheap to manufacture and maintain. This relatively means that carbureted motorcycles are cheaper to own and maintain compared to the fuel injected counterparts.

Cons-

1. They are very prone to cold start problems.

2. The working of a carburetor is highly affected by atmospheric pressure.

3. Throttle response is weak in a carbureted motorcycle.

4. Regular check ups and maintenance is required.