There have been many instances when a rider has chosen to use carbon rotors instead of the steel, but many have argued that the performance difference between the two of them isn’t actually very large, in fact, it’s almost negligible. So today in order to come one step closer to opening this old knot let’s take a look what carbon and steel disc brakes are and how can they make your life and ride better or worse. Though we have already talked about Carbon Disc Brakes on BikesMedia, this is going to be an objective comparison between the two.

Carbon Disc: Carbon disc brakes are also known as carbon-carbon because it is a composite material of reinforced carbon fiber in a matrix of graphite. Carbon has high tensile strength. The reason why only carbon is used is that it retains its solid shape at a temperature which easily melts another metal disc. Carbon discs were introduced to the track in early 90’s by Brembo. There were used by many MotoGP riders including the late great Nicky Hayden in an interview with him he described the brakes as perfect for “Hard & deep braking”.

Carbon disc brakes are also known as carbon-carbon because it is a composite material of reinforced carbon fiber in a matrix of graphite. Carbon has high tensile strength. The reason why only carbon is used is that it retains its solid shape at a temperature which easily melts another metal disc. Carbon discs were introduced to the track in early 90’s by Brembo. There were used by many MotoGP riders including the late great Nicky Hayden in an interview with him he described the brakes as perfect for “Hard & deep braking”.

They were first introduced in 500 cc class then into MotoGP and later into 250 cc for a short amount of time. Today the carbon disc brakes are used on almost every track but not in rainy conditions as the water disrupt the braking performance in these brakes because they need a constant high-temperature range to deliver optimum performance. It’s the fiber to fiber friction that occurs between the disc and the pads which generate the stopping force, the pads used in this case are also made up of carbon.

Disadvantages of carbon disc brakes:

Advantages of carbon disc: Steel disc brakes have been around for a long time they have been used for over 30 years and in the last 20 years; almost every bike that won MotoGP championship had steel disc braking setup on it. The steel which is used in our motorcycle goes by the name of SUS 410. It is a low carbon martensitic stainless steel in which carbon content is less than 0.15%. 410’sare considered in the automotive industry because it is more corrosion resistant as it contains 11.5% chromium whose concentration can further be increased to 13.5%.

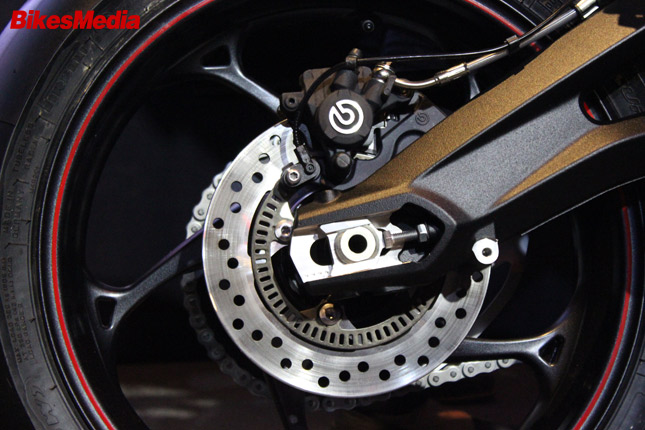

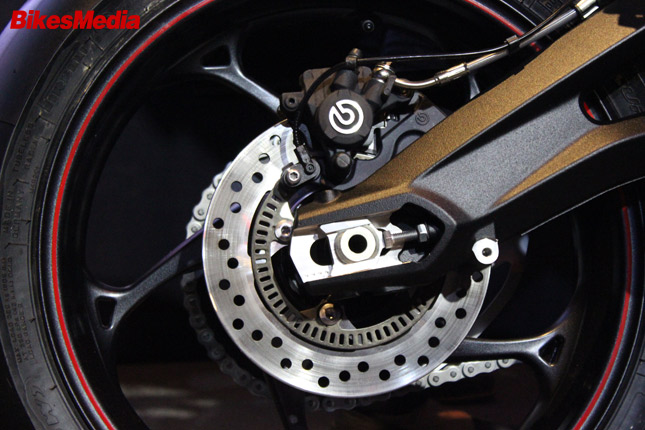

Steel disc brakes have been around for a long time they have been used for over 30 years and in the last 20 years; almost every bike that won MotoGP championship had steel disc braking setup on it. The steel which is used in our motorcycle goes by the name of SUS 410. It is a low carbon martensitic stainless steel in which carbon content is less than 0.15%. 410’sare considered in the automotive industry because it is more corrosion resistant as it contains 11.5% chromium whose concentration can further be increased to 13.5%.

Advantages of Steel disc:

The braking performance of any braking system is determined by transfer of braking torque and resistance to thermal mechanical stress and quick dispersion of heat generated. Which means in simple words is “Good brakes are the ones which can bring the bike to a stop quickly with less effort while generating as little heat as possible during the whole process”.

We have seen what both the discs bring to the table yet there is no clear answer to the question which one is better because it all depends upon the purpose for which you want to use it for. If you are a sponsored rider living in Spain with a ton load of company’s money to blow then carbon disc is what you want but if you’re a 22-year-old living in India with a pocket money then just be satisfied that you have a bike on which a steel disc brake is attached.

Again, the story is not yet over because not only discs but the type of tyres also determines the brake’s worth in a motorcycle but it’s a story for another time until then stay tuned to BikeMedia for more awesomeness.

By: Yetnesh Dubey

Carbon Disc:

Carbon disc brakes are also known as carbon-carbon because it is a composite material of reinforced carbon fiber in a matrix of graphite. Carbon has high tensile strength. The reason why only carbon is used is that it retains its solid shape at a temperature which easily melts another metal disc. Carbon discs were introduced to the track in early 90’s by Brembo. There were used by many MotoGP riders including the late great Nicky Hayden in an interview with him he described the brakes as perfect for “Hard & deep braking”.

Carbon disc brakes are also known as carbon-carbon because it is a composite material of reinforced carbon fiber in a matrix of graphite. Carbon has high tensile strength. The reason why only carbon is used is that it retains its solid shape at a temperature which easily melts another metal disc. Carbon discs were introduced to the track in early 90’s by Brembo. There were used by many MotoGP riders including the late great Nicky Hayden in an interview with him he described the brakes as perfect for “Hard & deep braking”. They were first introduced in 500 cc class then into MotoGP and later into 250 cc for a short amount of time. Today the carbon disc brakes are used on almost every track but not in rainy conditions as the water disrupt the braking performance in these brakes because they need a constant high-temperature range to deliver optimum performance. It’s the fiber to fiber friction that occurs between the disc and the pads which generate the stopping force, the pads used in this case are also made up of carbon.

Disadvantages of carbon disc brakes:

• Though the Carbon is cheap it’s the processing of the element which takes the cost up by a huge amount. A carbon disc used to cost around $4000 and a set of four pads were $2000 back in 1997, so they are certainly not easy to afford.

• If the carbon disc gets too hot, (beyond 800-degree Celsius) then because of the wear & tear the disc begins to warp.

• The longevity of the carbon disc brakes is an issue as they only last for up to a 1000 km.

• In rain, one can’t use the carbon disc brakes because of MotoGP regulations and also because the carbon brakes won’t work when they are continuously cooled down by water as they need to be in the range of 200-800 degree Celsius to work properly.

• If the carbon disc gets too hot, (beyond 800-degree Celsius) then because of the wear & tear the disc begins to warp.

• The longevity of the carbon disc brakes is an issue as they only last for up to a 1000 km.

• In rain, one can’t use the carbon disc brakes because of MotoGP regulations and also because the carbon brakes won’t work when they are continuously cooled down by water as they need to be in the range of 200-800 degree Celsius to work properly.

Advantages of carbon disc:

• Superb performance in dry hot weather, they keep the braking in peak condition throughout the race. They can withstand really high temperatures which can even melt metal discs. When kept within the optimum temperature range carbon disc brakes perform fabulously.

• They are light and strong and high in mass. They weigh in between the ranges of 1-1.2 kg. Even the individual carbon brake pads weigh in just at 50 gram each as opposed to the standard brake pads which weigh in at 125 g each.

Steel disc:

• They are light and strong and high in mass. They weigh in between the ranges of 1-1.2 kg. Even the individual carbon brake pads weigh in just at 50 gram each as opposed to the standard brake pads which weigh in at 125 g each.

Steel disc brakes have been around for a long time they have been used for over 30 years and in the last 20 years; almost every bike that won MotoGP championship had steel disc braking setup on it. The steel which is used in our motorcycle goes by the name of SUS 410. It is a low carbon martensitic stainless steel in which carbon content is less than 0.15%. 410’sare considered in the automotive industry because it is more corrosion resistant as it contains 11.5% chromium whose concentration can further be increased to 13.5%.

Steel disc brakes have been around for a long time they have been used for over 30 years and in the last 20 years; almost every bike that won MotoGP championship had steel disc braking setup on it. The steel which is used in our motorcycle goes by the name of SUS 410. It is a low carbon martensitic stainless steel in which carbon content is less than 0.15%. 410’sare considered in the automotive industry because it is more corrosion resistant as it contains 11.5% chromium whose concentration can further be increased to 13.5%.Advantages of Steel disc:

• They are very robust and compatible with a huge range of brake pads. They are highly resistant to wear and don’t shatter easily. They can obtain maximum heat resistance through hardening.

• They are relatively cheaper than carbon disc brakes and there is a lot of price range to choose from. Their range starts from as low as Rs 1200.

• The longevity is also a plus point in this case as if properly taken care, then the steel disc brakes in motorcycles can last as long as the bike itself. A regular change of brake pads is must to achieve.

• They are all out versatile they can be used in any weather condition, be it rain, the sun or the snow. Disc brakes perform almost equally well in all of them.

• The biggest advantage of them is that they can actually be used on the normal roads as well. The tracks for the past 20 years have been the improving ground for steel disc which is evident in today's motorcycles.

Disadvantages of steel disc:• They are relatively cheaper than carbon disc brakes and there is a lot of price range to choose from. Their range starts from as low as Rs 1200.

• The longevity is also a plus point in this case as if properly taken care, then the steel disc brakes in motorcycles can last as long as the bike itself. A regular change of brake pads is must to achieve.

• They are all out versatile they can be used in any weather condition, be it rain, the sun or the snow. Disc brakes perform almost equally well in all of them.

• The biggest advantage of them is that they can actually be used on the normal roads as well. The tracks for the past 20 years have been the improving ground for steel disc which is evident in today's motorcycles.

• They are not at par with the carbon brakes, as they are heavier and less strong than their carbon made counterparts.

• The performance carbon disc brakes are way above than steel discs as they dissipate heat much better and can achieve a higher coefficient of friction between carbon pads than steel discs.

• Carbon disc can sustain higher temperatures than steel disc before it breaks down and there is no chance of corrosion on carbon disc while there is still some chance of it on the steel discs.

Final thoughts:• The performance carbon disc brakes are way above than steel discs as they dissipate heat much better and can achieve a higher coefficient of friction between carbon pads than steel discs.

• Carbon disc can sustain higher temperatures than steel disc before it breaks down and there is no chance of corrosion on carbon disc while there is still some chance of it on the steel discs.

The braking performance of any braking system is determined by transfer of braking torque and resistance to thermal mechanical stress and quick dispersion of heat generated. Which means in simple words is “Good brakes are the ones which can bring the bike to a stop quickly with less effort while generating as little heat as possible during the whole process”.

We have seen what both the discs bring to the table yet there is no clear answer to the question which one is better because it all depends upon the purpose for which you want to use it for. If you are a sponsored rider living in Spain with a ton load of company’s money to blow then carbon disc is what you want but if you’re a 22-year-old living in India with a pocket money then just be satisfied that you have a bike on which a steel disc brake is attached.

Again, the story is not yet over because not only discs but the type of tyres also determines the brake’s worth in a motorcycle but it’s a story for another time until then stay tuned to BikeMedia for more awesomeness.

By: Yetnesh Dubey