The term Valvetrain or Valve Train is often used when we talk about 4-stroke engines, you might also come across terms like SOHC and DOHC while referring 4-stroke engine specifications. Ever wondered what these terms actually are? and what impact these technical jargon leave on performance or fuel economy of your bike?

Valvetrain:

The Valvetrain is a component/device to control the functioning of the Valves in a 4-stroke internal combustion engine. Valves are essentially used for efficient utilization of fuel and air mixture for proper combustion and expulsion of exhaust gasses after combustion takes place in the 4- stroke engine.

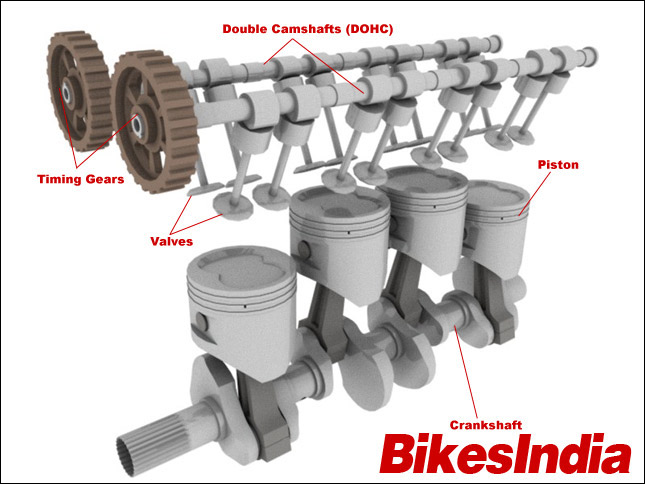

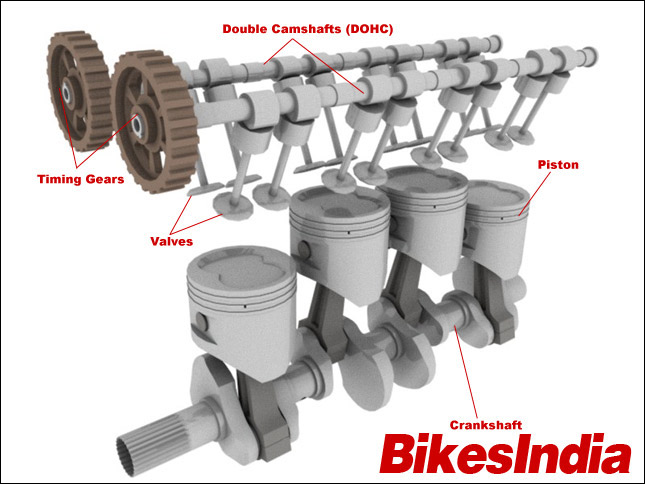

The Valvetrain is consists of Valves, Camshaft (or Camshafts depending upon the configuration of the Valvetrain), Rocker arms, Push Rods and Timing Gears (or Timing chain or Timing Belt depending upon the layout). Based on the position of Camshaft in the Engine the Valvetrain is broadly categorized into three; Cam-In-Block Valvetrain, Camless Valvetrain and Overhead Camshaft Valvetrain.

1. Single Overhead Camshaft (SOHC):

In a Single overhead camshaft there is only one Camshaft present in the individual cylinder head of an engine, for eg: in a V-Twin engine if there is one camshaft is deployed in each head then that engine's configuration would be called as SOHC though theoretically there are two Camshafts are available in the engine.

The Single Overhead Camshaft (SOHC) system is comparatively simpler than DOHC design as it has lesser components involved hence it has lesser effective mass as well. The other benefit of the simple design of SOHC configuration is its maintenance as it is easy to service and maintain. 2. Double Overhead Camshaft (DOHC):

2. Double Overhead Camshaft (DOHC):

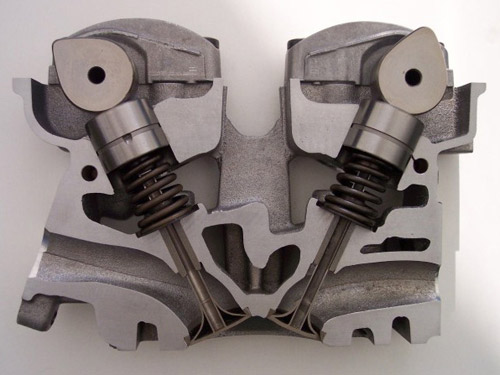

The Double Overhead Camshaft is featured with two Camshafts in a single cylinder head, for eg: in a V-Twin engine if there are 2 camshafts placed in each cylinder head and thereby there are 4 camshafts all in all used in that V-Twin engine, that configuration is called DOHC layout. Although there would be theoretically 4 camshafts available in the engine the system should have been called as Quad Camshaft configuration.

The Double Overhead Camshaft (DOHC) configuration is a bit modern type and are generally seen in modern race machines or performance machines. However the DOHC setup is comparatively complexed than SOHC but that complexity is often compromised with the enhanced performance capability, better internal gas dissipation and increased feasibility of putting valves at more acute angle.

Pros & Cons Of SOHC Layouts:

Pros & Cons Of DOHC Layout:

I hope this will help you to understand your mean machines a little more, if you find this article helpful or worth commenting please do share your opinion.

By: Farhan Kashif

I will try to explain these heavy terminologies in simple words for your better understanding. Lets start with the foremost thing that the Valvetrain is exclusively belong to 4-stroke engines since, as we all know that the 4-stroke engines are consist of Valves in it.

Valvetrain:

The Valvetrain is a component/device to control the functioning of the Valves in a 4-stroke internal combustion engine. Valves are essentially used for efficient utilization of fuel and air mixture for proper combustion and expulsion of exhaust gasses after combustion takes place in the 4- stroke engine.

The Valvetrain is consists of Valves, Camshaft (or Camshafts depending upon the configuration of the Valvetrain), Rocker arms, Push Rods and Timing Gears (or Timing chain or Timing Belt depending upon the layout). Based on the position of Camshaft in the Engine the Valvetrain is broadly categorized into three; Cam-In-Block Valvetrain, Camless Valvetrain and Overhead Camshaft Valvetrain.

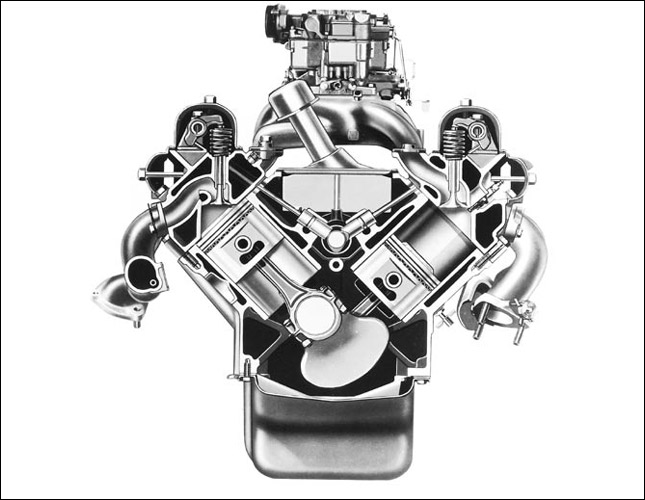

A. Cam-In-Block:

In this type of layout the Camshaft is placed well within the engine block and the valves are located over the head, that is why this type of configuration is also known as "Overhead Valve" (OHV). The valves are generally actuated either directly through camshaft or via Rocker arm or Push rods, the engines with OHV setup are also called as Pushrod engines. The classic example of Pushrod engine is of those our very own Royal Enfield motorcycles with old cast iron engine.

B. Camless:

As the term suggests in Camless configuration of Valvetrain there is no camshaft involve at all and the valves are actuated individually through technology like Solenoids.

C. Overhead Camshaft:

In Overhead Camshaft (OHC) configuration the Camshaft is placed above the valves present in the cylinder head of the engine. The Overhead Camshaft (OHC) is further divided into two based on the number of Camshafts present in the OHC configuration; SOHC and DOHC.

In this type of layout the Camshaft is placed well within the engine block and the valves are located over the head, that is why this type of configuration is also known as "Overhead Valve" (OHV). The valves are generally actuated either directly through camshaft or via Rocker arm or Push rods, the engines with OHV setup are also called as Pushrod engines. The classic example of Pushrod engine is of those our very own Royal Enfield motorcycles with old cast iron engine.

B. Camless:

As the term suggests in Camless configuration of Valvetrain there is no camshaft involve at all and the valves are actuated individually through technology like Solenoids.

C. Overhead Camshaft:

In Overhead Camshaft (OHC) configuration the Camshaft is placed above the valves present in the cylinder head of the engine. The Overhead Camshaft (OHC) is further divided into two based on the number of Camshafts present in the OHC configuration; SOHC and DOHC.

1. Single Overhead Camshaft (SOHC):

In a Single overhead camshaft there is only one Camshaft present in the individual cylinder head of an engine, for eg: in a V-Twin engine if there is one camshaft is deployed in each head then that engine's configuration would be called as SOHC though theoretically there are two Camshafts are available in the engine.

The Single Overhead Camshaft (SOHC) system is comparatively simpler than DOHC design as it has lesser components involved hence it has lesser effective mass as well. The other benefit of the simple design of SOHC configuration is its maintenance as it is easy to service and maintain.

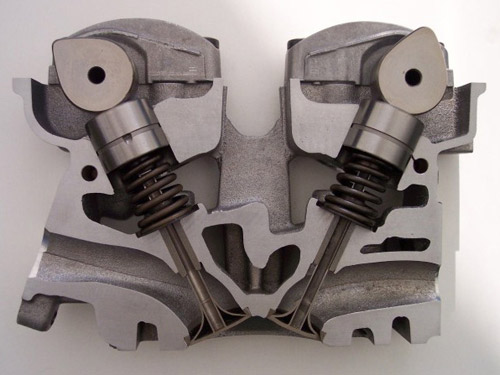

2. Double Overhead Camshaft (DOHC):

2. Double Overhead Camshaft (DOHC):The Double Overhead Camshaft is featured with two Camshafts in a single cylinder head, for eg: in a V-Twin engine if there are 2 camshafts placed in each cylinder head and thereby there are 4 camshafts all in all used in that V-Twin engine, that configuration is called DOHC layout. Although there would be theoretically 4 camshafts available in the engine the system should have been called as Quad Camshaft configuration.

The Double Overhead Camshaft (DOHC) configuration is a bit modern type and are generally seen in modern race machines or performance machines. However the DOHC setup is comparatively complexed than SOHC but that complexity is often compromised with the enhanced performance capability, better internal gas dissipation and increased feasibility of putting valves at more acute angle.

Pros & Cons Of SOHC Layouts:

-

SOHC Pros:

- Simple design

- Less effective mass

- Lower cost of manufacturing

- Easy to maintain

-

SOHC Cons:

- Less flexibility

- Limited space for port & spark plugs

- Less effective dissipation of gasses

Pros & Cons Of DOHC Layout:

-

DOHC Pros:

- More flexibility

- More space for port and spark plugs

- Greater flexibility in valve angles

- Better dissipation of gasses

- More efficient

-

DOHC Cons:

- More complexed

- Relatively difficult to maintain

- Less cost effective

I hope this will help you to understand your mean machines a little more, if you find this article helpful or worth commenting please do share your opinion.

By: Farhan Kashif